Introduction & Understanding Microbial Contamination in Oilfields

Formalin, a liquid mixture primarily composed of formaldehyde dissolved in water (often stabilized with small amounts of methanol), is widely known in laboratories and medical industries as a preservative. But within the oil and gas sector, formalin occupies a completely different and highly critical role. It is used as a strong, reliable biocide that protects equipment, fluids, and large-scale industrial systems from microbial contamination—one of the most persistent and costly problems in upstream and downstream operations.

Although newer biocides have entered the market in recent years, formalin remains an important part of oilfield chemical programs because it delivers rapid, broad-spectrum microbial control, works under harsh field conditions, withstands high temperatures, and remains economically feasible for large-volume industrial use. In environments where vast volumes of water interact with hydrocarbons—whether in drilling muds, completion fluids, produced water or refinery circuits—microbes can proliferate and cause catastrophic operational failures. Formalin is one of the few chemicals capable of addressing these challenges thoroughly and consistently.

This section will help lay the foundation for why formalin is still relevant today, beginning with the core problem it is designed to solve: microbial activity in oilfield systems.

Understanding the Real Threat: Microbial Contamination in Oilfield Environments

Microbial contamination may not be the first thing that comes to mind when people think of the oil and gas industry. Oil itself does not support microbial life, but most oilfield operations rely heavily on water—drilling fluids, injected seawater, produced water, fracturing fluids, cooling water, and storage systems. Wherever water is present, microorganisms can survive, multiply, and eventually trigger severe operational and safety problems.

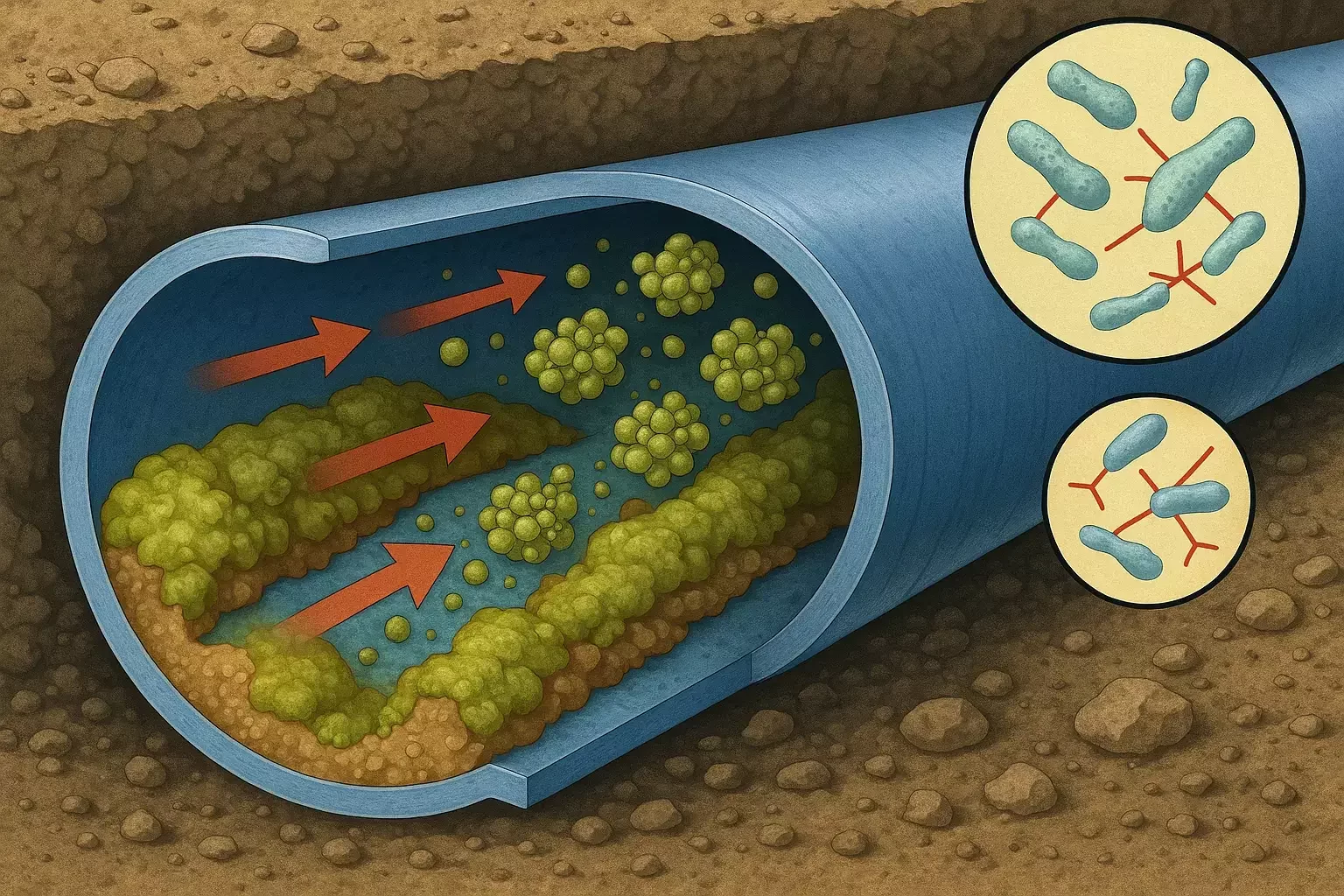

Oilfields typically deal with three major categories of harmful microorganisms: sulfate-reducing bacteria (SRBs), acid-producing bacteria (APBs), and slime-forming bacteria. Each type creates a unique set of challenges, and together they can severely damage equipment, disrupt production, and even impact the safety of personnel working on-site.

1. Sulfate-Reducing Bacteria (SRBs)

SRBs are considered the most destructive microorganisms found in oilfield environments. They thrive in oxygen-deprived (anaerobic) conditions, which are extremely common inside pipelines, separators, tanks, and subsurface formations. Their metabolism converts sulfate ions into hydrogen sulfide (H₂S), a toxic and corrosive gas. This single biological process is responsible for some of the most aggressive forms of internal corrosion in the industry.

Hydrogen sulfide attacks carbon steel, leading to rapid metal loss, pitting, and pipeline failures. It also degrades crude quality, causes souring of the reservoir, and poses serious health risks because H₂S is a lethal inhalation hazard even at low concentrations. Controlling SRBs is therefore not optional; it is a fundamental requirement for safe and uninterrupted production. Formalin is particularly effective against SRBs because it can penetrate biofilms, react quickly, and maintain stability even in challenging downhole conditions.

2. Acid-Producing Bacteria (APBs)

Unlike SRBs, acid-producing bacteria generate organic acids as metabolic byproducts when they degrade hydrocarbons or dissolved organic matter. These organic acids reduce the pH of surrounding fluids and initiate corrosion of metal surfaces. Over time, APBs can weaken casing, tubing, flowlines, and surface equipment, increasing maintenance costs and causing operational delays.

APBs also interfere with drilling fluid chemistry by breaking down polymers and other organic additives, which can destabilize drilling mud rheology and compromise wellbore stability. Once again, formalin’s strong antimicrobial properties make it a preferred choice where organic-acid corrosion is a concern.

3. Slime-Forming Bacteria and Biofilms

Biofilms pose a different kind of problem. Slime-forming bacteria secrete a sticky, gelatinous layer that adheres to metal surfaces. This biofilm traps dirt, solids, and other microorganisms, forming a protective shield that prevents conventional biocides from reaching the underlying metal. Beneath this layer, corrosion can progress unnoticed, creating localized weak spots that eventually result in leaks or catastrophic failures.

Biofilms also obstruct flow through pipelines and heat exchangers, decrease heat transfer efficiency, and alter process parameters. Removing or penetrating a biofilm is extremely difficult. Formalin, however, is one of the few biocides capable of breaking through the protective slime layer, killing both the surface bacteria and those embedded deeper within the biofilm structure.

Why Microbial Activity Becomes a Critical Issue in Oilfield Operations

Microbial contamination does not remain a minor annoyance; when left unchecked, it evolves into a multi-dimensional operational threat. Microbes can degrade drilling muds, reduce the effectiveness of completion fluids, sour reservoirs, promote internal corrosion, and drastically affect the quality of produced fluids. They also contribute to plugging in pipelines, fouling in separators, and the breakdown of essential polymers used in modern drilling and fracturing systems.

In many cases, microbial action directly increases chemical consumption. Corrosion inhibitors become less effective in the presence of biofilms. Polymers degrade faster when exposed to APBs. H₂S scavengers must work harder in systems colonized by SRBs. The result is a compounded cost—one part operational damage, and another part increased usage of other oilfield chemicals.

This is why microbial control remains central to both upstream and downstream operations. Whether drilling a new well, maintaining an offshore platform, transporting crude, or operating a refinery water circuit, controlling bacterial growth is essential to preserving both equipment and product quality.

Where Formalin Fits Into This Challenge

Formalin enters the picture as a robust, reliable, and economical biocide capable of addressing the entire spectrum of microbial activity—SRBs, APBs, and slime-forming bacteria. It is widely used in produced water treatment, drilling mud preservation, pipeline sanitation, injection water systems, tank cleaning, mud pits, refining water circuits, and even core sample preservation.

Its value lies in its speed, its ability to penetrate biofilms, its thermal stability, and its compatibility with many oilfield chemicals. For many mid-size and large-scale operators, formalin is one of the few options that effectively controls microbial activity without escalating treatment costs.

How Oilfields Use Formalin: Core Applications Across Upstream & Downstream Operations

Formalin today remains a trusted industrial biocide because it performs reliably in environments where many other biocides struggle. Oil and gas operations are exposed to extreme temperatures, variable pressures, high salinity, and complex fluid chemistries. A biocide must not only kill microorganisms, but also maintain stability under these conditions, remain effective in large volumes of water and hydrocarbons, and avoid rapid degradation. Formalin fulfills these criteria more consistently than many alternative treatments.

Below are the major applications where formalin plays a practical, high-value role across the oilfield.

1. Produced Water Treatment

Produced water is one of the most challenging fluid streams in the industry—it is a mixture of formation water, injection water, residual hydrocarbons, solids, and microbial populations. It often contains high sulfate concentrations, making it an ideal environment for SRB growth. As SRBs convert sulfate to hydrogen sulfide, both souring and corrosion begin to escalate.

Formalin is used to stabilize produced water systems by rapidly reducing the microbial load. When added in controlled concentrations, it disperses through the water column, penetrates biofilms, and neutralizes both free-floating and surface-adhered microorganisms. Treating produced water with formalin ensures that downstream equipment such as separators, heat exchangers, and reinjection pipelines remain free from microbial corrosion. This helps operators maintain equipment integrity, enhance water reuse strategies, and reduce the frequency of chemical maintenance shutdowns.

2. Drilling Fluids Preservation

Modern drilling fluids contain various organic polymers, starches, viscosifiers, and lubricants that microbes can easily degrade. When bacteria begin breaking down these organic molecules, drilling mud loses its viscosity, filtration properties, and carrying capacity. This leads to poor hole cleaning, unstable wellbores, excessive fluid loss, and overall drilling inefficiency.

Formalin acts as a preservative that prevents biological degradation of drilling mud. When introduced into active mud systems or storage pits, it inhibits bacteria responsible for polymer-breaking reactions. This helps maintain mud properties over long drilling intervals, especially in offshore operations or extended-reach wells where mud is reused multiple times. A stable drilling fluid not only maintains rheology but also improves rate of penetration, reduces circulation problems, and avoids expensive mud reconditioning.

3. Water Injection & Enhanced Oil Recovery (EOR) Systems

Water injection operations, including seawater injection, tertiary recovery systems, polymer floods, and EOR programs, depend heavily on microbial control. When untreated water enters a reservoir, SRBs can colonize the formation and produce hydrogen sulfide directly within the reservoir matrix. This process is known as reservoir souring, and once it begins, it becomes extremely difficult—and costly—to reverse.

Formalin is used as a pre-injection biocide to disinfect seawater or recycled produced water before it enters the injection pumps. The biocide interacts quickly with bacterial cells, denatures microbial proteins, and stabilizes the entire water handling system. Maintaining low microbial counts ensures that the injection tubing, wellheads, and reservoir remain less prone to souring. This ultimately protects production wells from corrosion, improves injection efficiency, and helps sustain higher recovery rates.

4. Pipeline and Storage Tank Sanitization

Pipelines carrying crude oil, multiphase fluids, or produced water accumulate internal deposits such as waxes, scales, and organic residues. These deposits provide an ideal foundation for microbial colonies, forming biofilms that shield bacteria from mechanical cleaning and lower-dose biocides. These biofilms become hotspots for pitting and under-deposit corrosion.

Formalin is often injected during pigging operations, line cleaning programs, and storage tank maintenance routines. Because of its ability to penetrate polymeric slime layers, formalin eliminates biofilm-forming bacteria beneath the deposit instead of merely killing surface organisms. This leads to a more complete sanitization of pipelines and tanks, ensuring better flow efficiency and reducing unexpected failures caused by internal corrosion.

5. Refinery Water Circuits and Cooling Systems

Downstream facilities such as refineries and petrochemical plants operate complex water systems—cooling water loops, heat exchangers, process water circuits, and wastewater treatment units. In the presence of heat, nutrients, and oxygen, microbial growth escalates quickly. Biofilms in cooling water systems can reduce thermal efficiency, increase energy consumption, and corrode heat exchangers at a rapid pace.

Formalin is used in controlled doses within refinery water systems to regulate bacterial activity, destroy algae, and inhibit the formation of microbial slime. Its advantage lies in its stability; it remains active even when water temperature fluctuates significantly or when exposed to hydrocarbons and dissolved solids. A stabilized water system translates into better heat exchange efficiency, lower power consumption, and fewer equipment shutdowns for chemical cleaning.

6. Core Sample Preservation

During exploration drilling, core samples are extracted from deep underground formations to analyze rock properties, reservoir characteristics, porosity, permeability, and hydrocarbon saturation. These samples must remain intact and uncontaminated for accurate evaluation.

Microbial degradation can alter the chemical composition of the core or break down organic materials within the matrix. To prevent this, cores are often soaked in dilute formalin solutions immediately after retrieval. The preservative action of formalin ensures that the sample remains unchanged during transport and laboratory analysis. This is especially important for biological or geochemical studies where organic integrity must be maintained.

7. Use in Downstream Petrochemical Preservation

In certain downstream applications, formalin is used to disinfect process vessels, preserve catalysts that are sensitive to microbial decay, and maintain the purity of stored reagents or organic compounds. Petrochemical production involves multiple chemical intermediates that degrade quickly when exposed to infection from microbes; formalin helps maintain stability in these high-value production environments.

8. Compatibility with Oilfield Chemical Programs

One of the understated advantages of formalin is its compatibility with various oilfield chemicals. It performs well alongside corrosion inhibitors, oxygen scavengers, scale inhibitors, EOR polymers, surfactants, and viscosifiers. This compatibility allows formulators to design integrated treatment packages that do not compromise the effectiveness of other chemical additives. Unlike some biocides that deactivate in the presence of strong acids, iron ions, or high salinity fluids, formalin remains effective across a wide range of oilfield conditions.

Safe Handling Practices, Operational Challenges & Dosage Management in Oilfield Use of Formalin

While formalin remains one of the most dependable biocides and preservatives in the oil and gas industry, its use requires careful management. This is because the same chemical properties that make it a powerful microbial killer also demand responsible handling, precise dosing, and regulatory awareness. In many ways, formalin is like any other high-performance industrial chemical — extremely effective when used correctly, but potentially hazardous when mishandled.

To ensure safe, sustainable and efficient operations, oilfield engineers follow specific protocols that make formalin both reliable and compliant.

1. Safe Handling & Worker Safety: Practical Guidelines for Field Operations

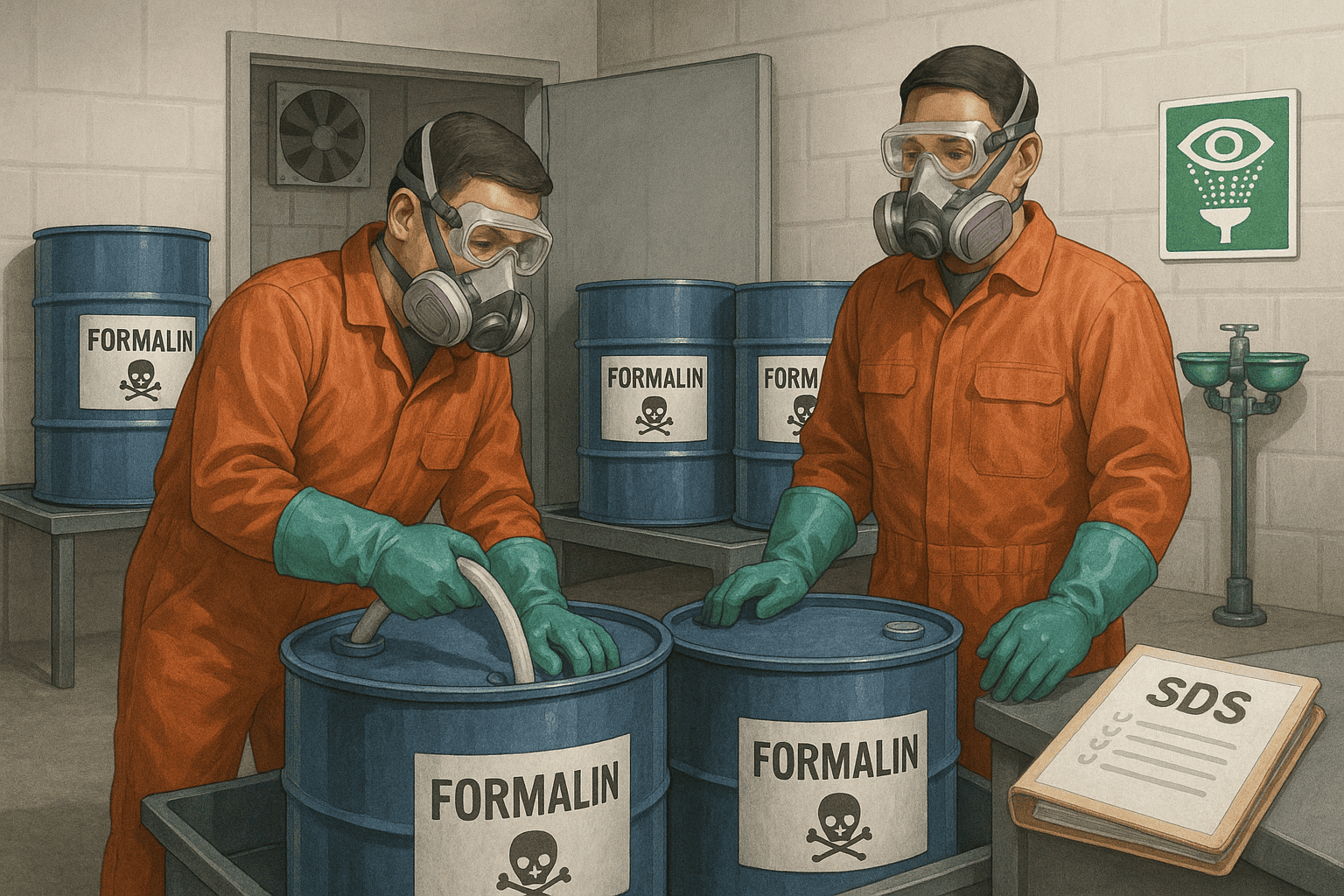

Formalin contains dissolved formaldehyde, a reactive compound known for its ability to cross-link biological molecules. This same action that kills microorganisms can irritate human skin, eyes, and respiratory pathways. Therefore, oilfield workers must take appropriate precautions during transportation, storage and injection.

In active drilling sites or offshore platforms, formalin drums are always labeled clearly, stored in well-ventilated areas, and handled with full PPE. Workers typically use chemical-resistant gloves, splash-proof goggles, and sometimes face masks or respirators when handling larger volumes or concentrated solutions.

One of the most important safety rules is to avoid breathing vapors in enclosed spaces. For this reason, dosing operations—whether in mud pits, produced water circuits or injection lines—are usually performed outdoors or in ventilated modules equipped with extraction fans.

Another practical guideline is avoiding direct mixing with strong oxidizers, acids, or amines unless part of a controlled formulation. These combinations may cause heat or gas release, which could lead to operational hazards. Trained personnel typically manage chemical transfers using sealed pumps and metering equipment, which prevent spills and exposure.

These measures establish a safe operating culture where formalin can be used effectively without compromising worker wellbeing.

2. Operational Challenges When Using Formalin in Oilfield Systems

Even though formalin is versatile, oilfield environments are complex and present some natural challenges. Chemical effectiveness can vary depending on salinity, temperature, pH, and the presence of other contaminants.

One common challenge is that formalin breaks down at very high temperatures, especially in systems exceeding 70–80°C. In hot produced water circuits or geothermal fields, this thermal breakdown can reduce its biocidal performance. Engineers solve this by adjusting the dosage or combining formalin with stabilizers that improve heat tolerance.

In systems with very high organic loads—such as heavy crude, emulsions, or oily produced water—formalin may require longer contact time to penetrate biofilms or reach surface-bound bacteria. To compensate, operators sometimes pre-flush systems or use mechanical agitation to improve dispersion.

Another practical challenge is the potential for odor. Formalin has a strong, distinct smell, which becomes noticeable during handling or tank venting. To address this, operators use closed-transfer systems, vapor scrubbers, or odor-neutralizing additives to minimize vapor emissions.

In certain refinery units or chemical plants, formalin may also interfere with catalysts or polymer reactions. In such cases, biocide selection and timing are carefully planned so that formalin dosing does not coincide with sensitive process steps.

While none of these challenges are difficult to manage, they highlight the importance of treating formalin as a controlled and monitored chemical rather than a simple commodity biocide.

3. Dosage Control: Why Precision Matters in Microbial Management

Effective biocide programs depend on achieving the right balance — too little formalin fails to control microbial growth, while too much increases cost and unnecessary chemical exposure. Oilfield microbiology varies widely between reservoirs, drilling fluids, and produced water systems; therefore, formalin dosing must be based on actual field conditions rather than guesswork.

Typically, oilfield laboratories perform microbial count tests such as ATP analysis, serial dilution cultures, or molecular testing to determine the baseline microbial load. Engineers then select a dosage that ensures rapid microbial kill while maintaining cost efficiency.

In drilling fluids, formalin dosages are often kept lower to avoid chemical interactions with mud additives. In water injection systems, higher dosages may be used during shock treatment to eliminate existing biofilms, followed by maintenance dosing to keep bacterial populations suppressed.

Injection rates are controlled using metering pumps that continuously feed formalin into flow lines. Automated dosing skids allow precise control based on real-time flow rates, ensuring consistent protection during production fluctuations.

Getting this dosage right has measurable effects: smoother flow lines, fewer microbial-induced corrosion cases, lower H₂S formation, and significantly reduced system downtime. Proper dosage control transforms formalin from a simple disinfectant into a strategic operational tool that protects both equipment and production output.

4. Environmental Considerations & Industrial Responsibility

As environmental regulations evolve globally, oil and gas operators place greater emphasis on environmentally responsible biocide use. Formalin, when managed correctly, can fit into sustainable operational frameworks.

In most cases, formaldehyde breaks down naturally into formic acid and eventually carbon dioxide and water, especially when exposed to sunlight, heat, or oxygenated environments. This biodegradation pathway minimizes its long-term ecological footprint.

However, operators still follow strict guidelines to avoid overuse or accidental release. Produced water containing formalin is treated in controlled wastewater systems where chemical residuals can be neutralized. Biological treatment units often degrade formaldehyde efficiently, making it manageable within refinery and petrochemical wastewater plants.

Environmental stewardship also includes using modern closed-transfer systems that minimize atmospheric vapor release. Many companies now prefer low-emission containers and dosing technologies to maintain compliance with air-quality guidelines.

Global frameworks such as the EPA, REACH, and individual national petroleum boards require regular monitoring and reporting. By aligning formalin programs with these regulations, operators demonstrate both compliance and commitment to responsible resource management.

5. Industry Trends: Moving Toward Safer, Synergistic & Eco-Friendly Alternatives

While formalin continues to hold strong relevance, the industry is gradually exploring complementary biocides and hybrid solutions. Some operators use glutaraldehyde blends, THPS-based biocides, or non-oxidizing alternatives in combination with formalin to create multi-stage microbial control strategies. This allows for lower dosages of formalin while achieving higher biocidal efficiency.

A growing trend is the integration of real-time microbial monitoring tools and automated dosing systems. These innovations ensure chemicals are used only when necessary, reducing waste and ensuring consistent field performance.

There is also research into biodegradable and green biocide formulations that offer similar performance but with reduced hazard profiles. While these are still emerging, formalin remains an essential benchmark against which newer alternatives are measured.

Conclusion: Why Formalin Remains a Trusted Chemical in the Oil & Gas Industry

Across upstream and downstream operations, formalin continues to play a critical role in maintaining oilfield cleanliness, operational efficiency, and microbial control. Its unique ability to penetrate biofilms, inhibit bacterial growth, and stabilize sensitive fluids makes it far more than a routine industrial biocide — it is a strategic chemical that helps operators safeguard pipelines, protect reservoirs, and preserve equipment integrity.

In drilling fluids, formalin helps maintain mud quality by suppressing microbial degradation. In completion and injection systems, it prevents bacterial contamination that could otherwise lead to corrosion or reservoir souring. In refineries, it contributes to smoother operations by protecting cooling water, storage tanks, and process units from microbial fouling.

Despite its strong performance, formalin’s safe use depends on proper handling, precise dosing, and thorough understanding of environmental responsibilities. Oilfield teams must follow established guidelines for PPE, storage, and injection, while leveraging modern monitoring and dosing systems to ensure both efficiency and compliance.

The industry is evolving with greener alternatives and advanced technologies, but formalin remains an important benchmark — a well-understood, reliable, and cost-effective solution that continues to support large-scale operations worldwide. As operators balance performance with sustainability, formalin’s adaptability ensures it will remain a valuable component in oilfield chemical programs for years to come.

FAQs: Common Questions About Formalin Use in Oil & Gas Operations

1. Why is formalin preferred over other biocides in the oilfield?

Formalin is fast-acting, cost-effective, and capable of penetrating microbial biofilms that many other biocides fail to reach. It provides consistent performance across drilling muds, produced water, injection systems, and refinery circuits, making it one of the most versatile biocide options available.

2. Is formalin safe for use in high-temperature oilfield environments?

Formalin is stable up to moderate temperatures, but it begins to degrade when exposed to very high heat. In hot environments, engineers may adjust dosage or use stabilizers to maintain effectiveness. In some extreme-temperature systems, non-oxidizing biocides may be used alongside or instead of formalin.

3. How does formalin help protect pipelines and equipment?

Microbial growth, especially from sulfate-reducing bacteria, can lead to corrosion, scale, gas pockets, and emulsion instability. Formalin suppresses these microbes by disrupting their cellular structure, preventing corrosion and ensuring smoother flow and cleaner equipment surfaces.

4. Does formalin pose environmental risks?

Formalin must be handled responsibly, but it biodegrades relatively quickly into simpler, less harmful compounds. When used in controlled doses and neutralized in wastewater systems, it can be managed safely under standard environmental regulations. Most countries allow formalin use with proper documentation and monitoring.

5. Can formalin be replaced entirely by newer biocides?

While alternatives like glutaraldehyde, THPS, or synergistic blends are increasingly used, formalin remains irreplaceable in many scenarios due to its penetration ability, speed, affordability, and compatibility with oilfield fluids. In most cases, operators prefer hybrid programs rather than full replacement.