Barite, a naturally occurring mineral composed of barium sulfate (BaSO₄), is a crucial raw material in various industries, with the oil and gas sector being one of its primary consumers. Known for its high density, chemical stability, and non-toxic nature, barite serves a vital function in drilling operations, where it is primarily used as a weighting agent in drilling fluids. These fluids help control pressure, prevent blowouts, and ensure the smooth extraction of oil and gas from deep underground reservoirs.

With the continuous rise in global energy demand, the exploration and production of hydrocarbons have become more intensive, driving the need for high-quality drilling materials like barite. Its unique properties make it indispensable for maintaining wellbore stability and enhancing the efficiency of drilling processes. As the industry evolves and explores deeper and more complex reservoirs, the significance of barite in ensuring safe and cost-effective drilling operations continues to grow.

This blog delves into the critical role of barite in the oil and gas industry, examining its key properties, widespread applications, major global sources, and the future prospects of this essential mineral.

Understanding Barite: Properties and Composition

Barite is a remarkably dense mineral, boasting a high specific gravity that typically falls between 4.2 and 4.5. This exceptional density makes it an ideal weighting agent in drilling muds, a critical component in oil and gas exploration. Beyond its density, barite is chemically stable, non-toxic, and highly resistant to high temperatures and pressures, ensuring its reliability in demanding industrial environments.

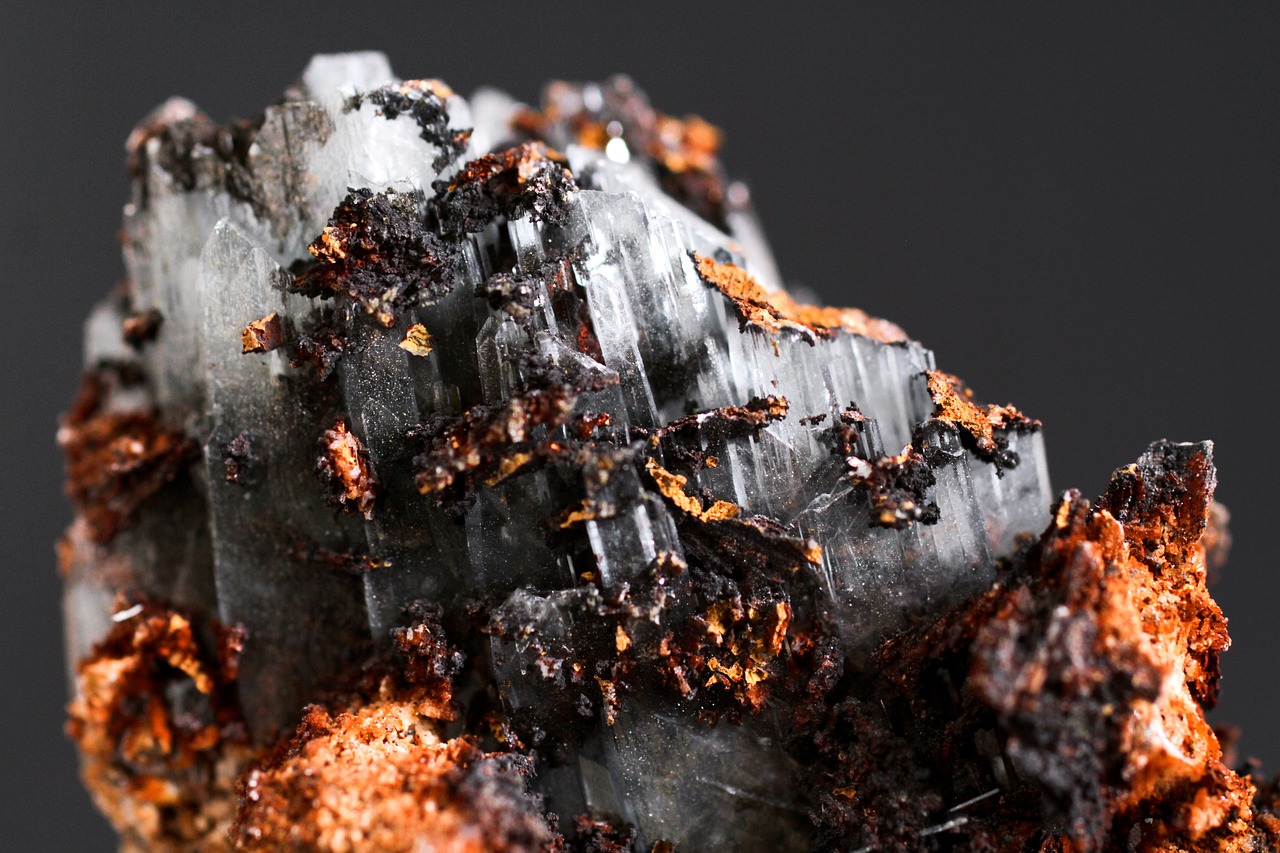

Visually, barite is often white or colorless, but its appearance can vary depending on the presence of impurities. It may exhibit shades of blue, brown, gray, or even red, adding to its diverse natural characteristics. These unique properties make barite indispensable in drilling operations and various other industrial applications, solidifying its importance across multiple sectors.

The Importance of Barite in Drilling Fluids

One of the most crucial applications of barite in the oil and gas industry is its role in drilling fluids, commonly known as drilling muds. These specialized fluids perform multiple essential functions, including cooling and lubricating the drill bit, carrying rock cuttings to the surface, and maintaining well pressure to prevent dangerous blowouts. Without effective drilling fluids, operations in high-pressure and deep-drilling environments would be significantly more challenging and risk-prone.

How Barite Enhances Drilling Fluid Performance

1. Weighting Agent: The primary purpose of adding barite to drilling fluids is to increase their density. This added weight helps control formation pressures and counterbalance high-pressure zones encountered during drilling, reducing the risk of well blowouts. The high specific gravity of barite (4.2–4.5) makes it an optimal choice for this application.

2. Wellbore Stability: Maintaining wellbore integrity is critical in drilling operations. By increasing the hydrostatic pressure in the wellbore, barite helps stabilize the drilled hole, preventing formation collapse and ensuring smooth drilling progress.

3. Filtration Control: Barite contributes to filtration control by forming a dense filter cake on the wellbore walls. This barrier minimizes fluid invasion into permeable formations, reducing formation damage and improving well productivity.

4. Minimizing Differential Sticking: Differential sticking occurs when the drill pipe gets stuck against the wellbore due to pressure differences. The weight provided by barite helps counteract this issue, reducing the chances of costly operational delays and ensuring uninterrupted drilling.

By enhancing drilling fluid performance in these ways, barite plays an indispensable role in ensuring safe, efficient, and cost-effective oil and gas exploration.

Global Sources and Production of Barite

Barite is mined across various regions worldwide, with some countries playing a more dominant role in production and export. As a critical mineral for the oil and gas industry, its availability and supply chain dynamics significantly impact global drilling operations. While several nations contribute to barite mining, a few key players control the majority of global output.

Major Barite Reserves and Mining Operations

1. China: As the world’s largest producer, China accounts for a significant share of global barite output. The country exports substantial quantities to major oil and gas markets, ensuring a steady supply for drilling operations worldwide.

2. India: India is another leading barite producer, with vast deposits primarily concentrated in the state of Andhra Pradesh. The country supplies both domestic industries and international markets, playing a vital role in global barite trade.

3. United States: Although the U.S. is one of the largest consumers of barite, its domestic production is relatively limited. Key mining operations are found in Nevada and Georgia, but the country still depends heavily on imports to meet its demand.

4. Morocco and Mexico: These nations serve as important global suppliers, contributing significantly to the international barite trade. Their strategic locations allow them to export efficiently to various markets, including North America and Europe.

The global barite supply chain remains crucial for oil and gas drilling activities, with production and trade dynamics influencing market stability and pricing. As demand continues to grow, ensuring a sustainable and reliable supply of high-quality barite remains a priority for the industry.

Market Trends and Demand for Barite in the Oil and Gas Sector

The demand for barite is directly tied to oil and gas exploration and production activities. When oil prices rise, drilling activities increase, leading to higher consumption of barite. Conversely, during periods of low oil prices, barite demand declines.

Factors Influencing Barite Demand

Oil Prices: Higher crude oil prices drive increased drilling activities, boosting demand for barite-based drilling fluids.

Exploration in Deepwater and Unconventional Reserves: The development of shale gas and deepwater drilling has increased the need for high-density drilling fluids, amplifying barite consumption.

Environmental Regulations: Stringent environmental policies may affect barite mining and processing, influencing its availability and cost.

Alternative Weighting Agents: Although barite remains the preferred weighting material, ongoing research into synthetic and alternative materials may impact its long-term market dynamics.

Challenges Facing the Barite Industry

Despite its indispensable role in the oil and gas sector, the barite industry encounters several challenges that affect its availability, quality, and sustainability. These challenges can influence pricing, supply stability, and overall market dynamics.

1. Supply Chain Disruptions:

The global barite supply is concentrated in a few key regions, making the industry vulnerable to supply chain disruptions. Factors such as trade restrictions, geopolitical tensions, and logistical challenges can impact availability and lead to price volatility. The reliance on imports in major consumer markets, like the United States, further exacerbates this issue.

2. Quality Variability:

Barite deposits vary in purity, with differences in specific gravity, mineral composition, and the presence of impurities. These variations can affect its performance as a weighting agent in drilling fluids, requiring additional processing to meet industry standards. Maintaining consistent quality is essential for ensuring drilling efficiency and preventing operational issues.

3. Environmental Concerns:

Mining and processing barite can have significant environmental impacts, including habitat destruction, water pollution, and excessive energy consumption. If not managed responsibly, these activities can lead to long-term ecological degradation. Sustainable mining practices, waste management strategies, and stricter environmental regulations are crucial for minimizing the industry’s footprint.

Addressing these challenges requires investment in alternative sources, improved processing technologies, and environmentally responsible mining practices to ensure a stable and sustainable barite supply for the future.

Future Outlook for Barite in the Oil and Gas Industry

As the global energy industry continues to evolve, barite's role in drilling operations will remain vital. Advancements in drilling technology, the expansion of offshore exploration, and the increasing need for high-performance drilling fluids will sustain barite demand. Additionally, improvements in recycling and alternative sourcing strategies may help mitigate some of the supply chain challenges.

Conclusion

Barite is an essential component of the oil and gas industry's drilling operations, serving as a critical weighting agent in drilling fluids. Its unique properties, including high specific gravity and chemical stability, make it indispensable in ensuring efficient and safe drilling. While challenges such as supply chain disruptions and environmental concerns persist, barite's significance in the sector is unlikely to diminish anytime soon. As global energy demands grow, so will the need for this invaluable mineral, reinforcing its crucial role in the future of oil and gas exploration.