Understanding the Chemistry

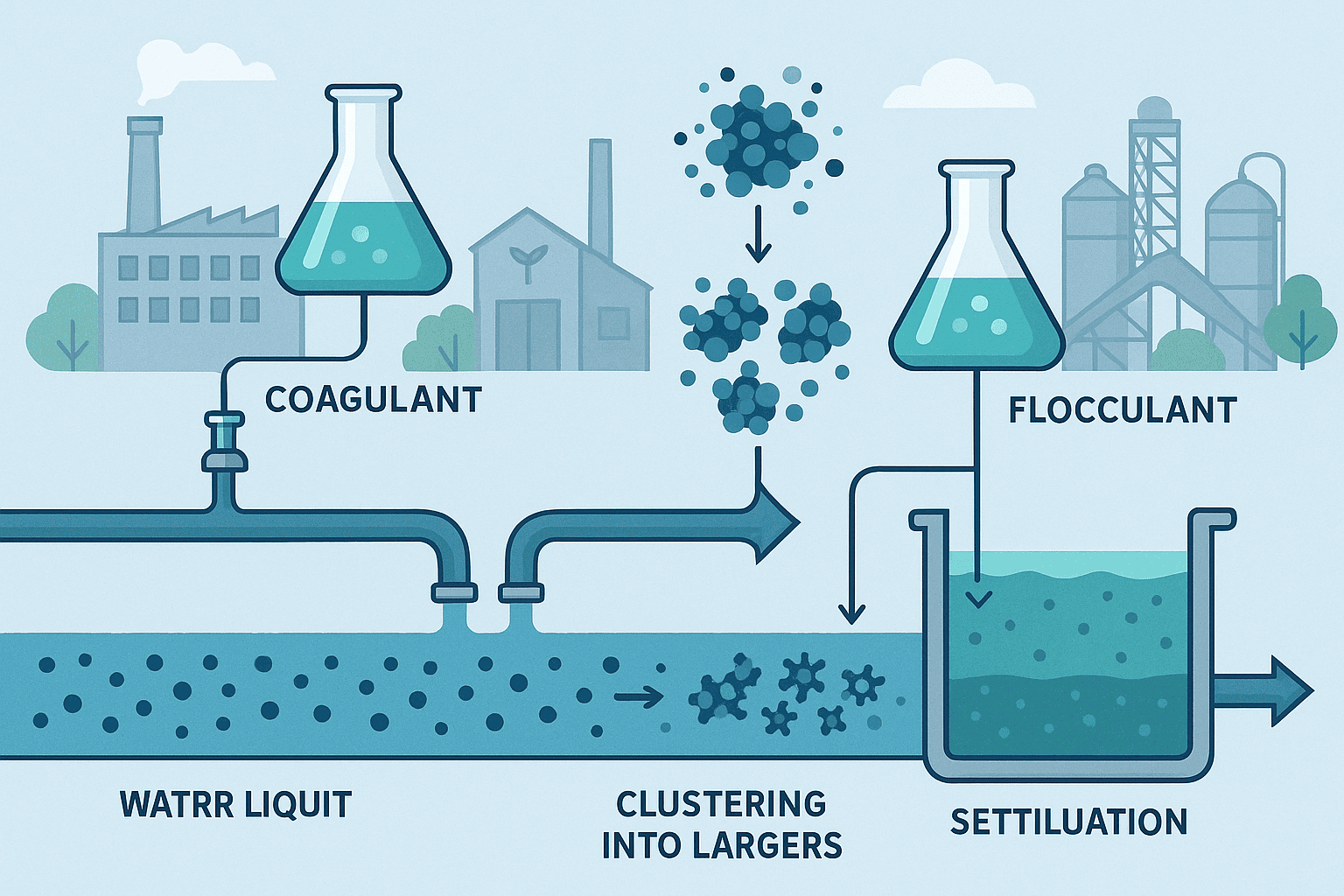

At its core, coagulant-flocculant chemistry is about transforming process streams by removing fine, suspended particles that standard filtration simply can't handle. These particles—often colloidal in nature—remain stable in water due to their surface electrical charges, resisting natural settling or aggregation.

Coagulants are typically positively charged metal salts (like aluminum or iron compounds) or synthetic organic polymers. When added to water, they neutralize the negative charges on the surface of suspended particles, breaking the electrostatic repulsion that keeps them apart. This destabilization allows the particles to begin clustering together.

Flocculants come next: these are long-chain polymer molecules designed to bind destabilized particles together. Through a process called bridging, flocculants link smaller aggregates into larger, visible "flocs." These flocs are much easier to remove via sedimentation, flotation, or filtration.

This dual-step approach is not just limited to wastewater—it's critical in any industrial process requiring solid-liquid separation, from mineral extraction and chemical production to beverage manufacturing. Mastering the precise chemistry and dosing of coagulants and flocculants leads to:

- Faster and more complete particle removal

- Lower chemical consumption

- Reduced sludge generation

- Higher process water reuse rates

- Improved product purity and consistency

By understanding how these chemicals work together, industries can unlock significant improvements in efficiency, sustainability, and cost savings.

Coagulants are charged molecules (often metal salts or polymers) that destabilize fine particles, making them easier to group together. Flocculants are long-chain polymers that link these destabilized particles into larger aggregates (flocs), which can then be easily separated from the process stream.

This two-step approach is crucial in:

- Solid-liquid separation

- Wastewater treatment

- Sludge dewatering

- Raw material recovery

- Product quality improvement

7 Game-Changing Coagulant-Flocculant Solutions for 2025

1. Polyamine-Based Coagulants

Polyamine-based coagulants are a class of water-soluble polymers characterized by the presence of multiple amine groups along their chains. These amine groups provide a strong positive charge density, making polyamines exceptionally effective at neutralizing the negatively charged surfaces of colloidal particles commonly present in industrial wastewater and process streams. When dosed into water, these coagulants act rapidly—breaking the electrostatic stability that keeps fine particles suspended.

What sets polyamine-based coagulants apart is their versatility and adaptability. They can be fine-tuned for a wide range of pH conditions and industrial contaminants, allowing for rapid, targeted treatment even when wastewater composition changes frequently, such as in batch processes or facilities handling diverse waste streams. Their action often leads to faster sedimentation and larger, more robust flocs, which are easier for downstream flocculants to aggregate and remove.

In addition, polyamines are frequently used in combination with inorganic coagulants or as a "booster" to enhance overall process efficiency. This dual-function capability often results in lower total chemical consumption, improved removal of organic and inorganic pollutants, and more stable operation of clarifiers, thickeners, and filtration equipment.

2. Aluminum Chloralhydrate (ACH)

Aluminum Chlorohydrate (ACH) stands out as one of the most advanced and efficient inorganic coagulants used in modern water and wastewater treatment. Unlike traditional alum or ferric salts, ACH is a pre-hydrolyzed aluminum salt with a unique polymerized structure, giving it a much higher charge density. This high charge density means ACH can neutralize suspended particle charges much more effectively and at lower dosages, delivering rapid coagulation even in difficult process streams.

One of ACH’s key advantages is its ability to form large, dense, and rapidly settling flocs. This ensures faster clarification, clearer effluent, and easier separation of solids from liquids—crucial for high-throughput operations like municipal water plants, industrial textile dyeing, and paper manufacturing. ACH also works well across a broad pH range, making it versatile for different water chemistries and reducing the need for pH adjustment.

Another significant benefit is reduced sludge generation. Because ACH is more efficient at binding and settling particles, it produces less residual sludge than conventional aluminum or iron salts. This translates to lower sludge handling, disposal costs, and reduced environmental impact—key factors for industries focused on sustainability and compliance.

By combining strong coagulation power, broad applicability, and environmental advantages, ACH has become a preferred solution for facilities seeking reliable, cost-effective, and sustainable water treatment.

3. Biopolymer Flocculants

Biopolymer flocculants are redefining the standard for sustainable water treatment. These flocculants are derived from renewable, natural sources such as starch, guar gum, and chitosan, making them both eco-friendly and biodegradable. Unlike synthetic polymers, biopolymers break down naturally after use, eliminating concerns about persistent environmental pollutants.

Their effectiveness in forming large, stable flocs enables efficient removal of suspended solids and contaminants across a broad range of industrial sectors, from food processing to mining. Biopolymer flocculants are especially valued by organizations aiming to meet stringent discharge limits or seeking to bolster their green credentials. Their gentle action is compatible with sensitive biological systems, and they often integrate seamlessly into existing biological treatment processes. Adopting biopolymer flocculants not only improves solid-liquid separation but also supports regulatory compliance and enhances the sustainability profile of industrial operations.

4. Cationic Polyacrylamide (CPAM)

Cationic Polyacrylamide (CPAM) is a powerhouse flocculant renowned for its versatility and superior performance in sludge thickening and dewatering processes. Its strong positive (cationic) charge allows it to efficiently attract and bind with negatively charged suspended particles, organic matter, and colloids. This results in the rapid formation of dense, easily settled or filtered flocs, streamlining the separation of solids from liquid.

CPAM’s benefits extend beyond just efficient clarification. Its use leads to improved water recovery rates, meaning more treated water can be reused in the process. It also produces drier, more compact sludge, reducing costs associated with sludge transport and disposal. Its adaptability has made it indispensable in diverse industries, including municipal wastewater treatment, food and beverage processing, petrochemicals, and pulp and paper manufacturing. With CPAM, plants achieve higher operational efficiency, lower operating costs, and better environmental compliance.

5. Hybrid Organic-Inorganic Blends

Hybrid organic-inorganic blends are engineered to tackle complex industrial water challenges where single-agent solutions fall short. These advanced products merge the rapid charge-neutralizing capability of inorganic metal salts (such as aluminum or iron coagulants) with the superior bridging and floc-strengthening properties of high-molecular-weight organic polymers. This synergy provides rapid destabilization of diverse contaminants—including colloids, oils, and variable-sized particulates—while forming large, dense, and robust flocs for effective removal.

One of the core advantages of hybrid blends is their adaptability. They perform consistently across a range of water chemistries and fluctuating process conditions, enabling process engineers to fine-tune treatment protocols for maximum efficiency. Industries such as oil & gas, food and beverage, and chemical manufacturing benefit from hybrids’ ability to handle high turbidity, emulsions, and oily waste streams—delivering compliance and process stability even as influent quality changes.

6. Color Removal Agents

Color removal agents play a crucial role in industries like textiles, dye manufacturing, and food processing, where effluent discoloration poses regulatory and reputational risks. These specialized coagulants and flocculants are formulated to selectively target and neutralize chromophoric (color-causing) molecules—often complex, stable organic compounds. They work by breaking the chemical structure of color bodies or binding them into larger aggregates, making them removable by sedimentation or filtration.

Modern color removal agents are often compatible with biological and advanced oxidation treatments, improving overall plant efficiency and regulatory compliance. The outcome is crystal-clear, aesthetically improved effluent that meets stringent discharge norms and enhances a facility’s environmental image.

7. Shear-Resistant Flocculants

Shear-resistant flocculants are specifically engineered to maintain their structural integrity and performance even under conditions of intense mixing, turbulence, and mechanical stress—situations commonly encountered in many industrial process streams. Traditional flocculants can form large aggregates but are prone to breaking apart when subjected to high shear forces in pumps, pipes, or reactors, leading to suboptimal separation and increased carryover of solids.

The latest generation of shear-resistant flocculants features advanced molecular architectures, such as cross-linked polymer networks or reinforced chain designs, that provide extra durability and flexibility. This ensures that once flocs are formed, they remain intact throughout the agitation and transfer stages, resulting in more reliable solid-liquid separation, better water clarity, and improved downstream processing.

Industries like mining, pulp and paper, and food processing—where high-shear environments are routine—especially benefit from these innovations. By reducing floc breakup, shear-resistant flocculants help maximize the recovery of valuable solids, reduce process interruptions, and improve the efficiency of thickeners, clarifiers, and filtration systems. Ultimately, these flocculants contribute to greater operational stability, resource efficiency, and compliance with stringent discharge requirements.

Shear-resistant flocculants are specifically designed for use in industrial processes where wastewater is subject to high turbulence, strong agitation, or intense mixing. Unlike standard flocculants that can break apart in such environments, shear-resistant versions have reinforced molecular structures or cross-linking that maintain floc integrity from formation through to separation.

Conclusion

Coagulant-flocculant chemistry stands as a cornerstone of industrial process optimization and sustainability. In an era where water reuse, zero liquid discharge, and regulatory demands are only increasing, these advanced chemicals empower industries to tackle complex challenges with confidence and precision. From achieving crystal-clear effluent and efficient raw material recovery to dramatically lowering sludge volumes and overall treatment costs, the right coagulant-flocculant solutions transform operational efficiency and environmental responsibility.

The innovations profiled in this blog—spanning polyamine-based coagulants to shear-resistant flocculants—highlight just how far the science has come, offering unprecedented control over water quality and process reliability. By embracing these breakthroughs, industries not only stay compliant and competitive but also champion a cleaner, more resource-efficient future. Strategic investment in modern coagulant-flocculant chemistry is more than a technical upgrade—it's a commitment to operational excellence, regulatory leadership, and true sustainability.