Introduction

In the oil and gas industry, efficiency, purity, and safety are non-negotiable. Whether it’s separating oil from water, purifying drilling fluids, or treating industrial wastewater, every process depends on chemicals that enhance stability and performance. One such essential chemical is Polyaluminum Chloride (PAC)—a powerful coagulant that has become a cornerstone in water treatment and oilfield operations worldwide.

Over the last few decades, PAC has steadily replaced traditional coagulants like alum (aluminum sulfate) and ferric chloride due to its superior coagulation ability, reduced sludge generation, and cost efficiency. It plays a critical role not just in the water treatment process, but also in oilfield drilling mud conditioning, emulsion breaking, and refinery wastewater management.

This blog will help you understand PAC from the ground up—its chemistry, industrial relevance, how it’s used in oil and gas, its benefits, safety measures, and the best application practices. Even if you’re not from a technical background, you’ll walk away with a clear picture of why PAC matters and how it supports oil and gas operations globally.

What is Polyaluminum Chloride (PAC)?

Polyaluminum Chloride (often abbreviated as PAC) is an inorganic polymer-based coagulant primarily used in water purification, wastewater treatment, and chemical industries. It is a highly efficient compound derived from aluminum hydroxide and hydrochloric acid, forming a polymer with the chemical formula:

[Alₙ(OH)ₘCl₍3n–m₎]ₓ

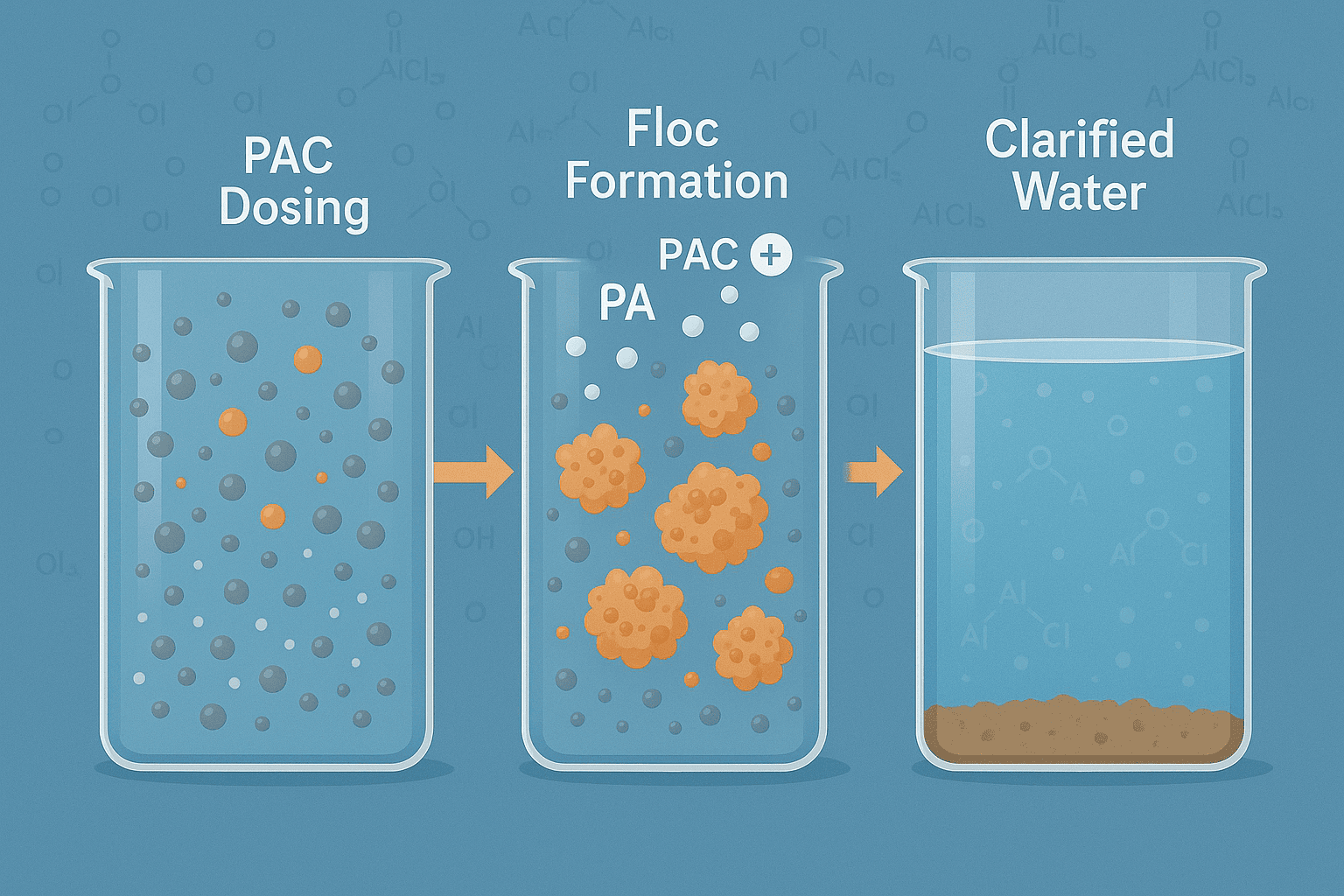

In simpler terms, it’s a blend of aluminum ions and chloride ions bonded in such a way that they have strong charge neutralization capabilities. This property allows PAC to quickly destabilize and aggregate suspended solids, oil droplets, and organic matter in water — a crucial process in oil and gas operations.

PAC typically appears as a yellow or light brown liquid or powder, depending on its grade and concentration. It’s available in several formulations like PAC 10%, PAC 18%, and PAC 28%, indicating varying levels of basicity (degree of polymerization). Each grade suits different industrial needs — from potable water purification to heavy-duty wastewater or oilfield applications.

Chemical Structure and Properties

Property | Details |

Chemical Formula | [Alₙ(OH)ₘCl₍3n–m₎]ₓ |

Molecular Weight | Variable (depends on polymer length) |

Appearance | Yellowish powder or liquid |

Solubility | Completely soluble in water |

pH (1% solution) | 3.5–5.0 |

Basicity | 30–85% (depends on formulation) |

Storage Stability | Excellent under dry conditions |

Reactivity | Strong coagulant and flocculant properties |

What makes PAC remarkable is that it contains both positive and polymeric species that can effectively neutralize negatively charged particles. When added to a liquid system (like oil-contaminated water), these particles aggregate into larger clusters (flocs) that can easily settle or be filtered out.

Comparison with Traditional Coagulants

Before PAC, industries relied heavily on alum (Al₂(SO₄)₃) or ferric chloride (FeCl₃). While effective, these older coagulants often required higher dosages, created more sludge, and sometimes caused pH imbalance in treated water.

Parameter | PAC | Alum / Ferric Chloride |

Dosage Requirement | Low | High |

Sludge Generation | Minimal | High |

pH Sensitivity | Stable | Requires correction |

Reaction Speed | Fast | Moderate |

Effect on Equipment | Non-corrosive | Corrosive |

Overall Efficiency | High | Moderate |

Thanks to these improvements, PAC has become a preferred choice in industries that deal with large-scale water or chemical treatment—especially oil refineries, petrochemical plants, and drilling companies.

Grades and Types of PAC

PAC is manufactured in different grades depending on its intended use:

Water Treatment Grade:

Used for drinking water, municipal sewage, and general wastewater treatment.Industrial Grade:

Applied in paper manufacturing, textiles, dyeing, and particularly oilfield wastewater treatment.High-Purity Grade:

Used in pharmaceuticals, cosmetics, and food processing, where ultra-clean coagulation is needed.

For oil and gas purposes, industrial-grade PAC is typically used due to its strong flocculating ability, corrosion resistance, and cost-effectiveness.

Role of Polyaluminum Chloride (PAC) in the Oil & Gas Industry

1. The Importance of Chemical Treatment in Oil & Gas

In oil and gas operations, managing fluids efficiently is a science in itself. Whether it’s drilling fluids, completion brines, or refinery wastewater — every stage involves large volumes of liquids that must be treated, stabilized, or separated. Contaminants like suspended solids, emulsified oil, heavy metals, and organic matter can severely affect productivity, equipment integrity, and environmental compliance.

That’s where Polyaluminum Chloride (PAC) steps in as a multifunctional treatment chemical. From drilling mud stabilization to produced water purification, PAC serves as a vital component for maintaining clean, efficient, and environmentally safe operations.

2. Applications of PAC in the Oil & Gas Sector

Let’s look at where PAC fits into various oil and gas processes:

A. Drilling Operations

During drilling, maintaining the right properties of drilling mud (or drilling fluid) is crucial. The mud must lubricate the drill bit, carry rock cuttings to the surface, and stabilize the wellbore walls. However, contaminants such as clay, silt, and suspended solids can make the fluid unstable or too viscous.

Role of PAC:

- PAC acts as a flocculant and coagulant that helps remove unwanted fine particles from drilling fluids.

- It promotes solid-liquid separation, allowing for the recycling and reuse of the mud.

- Enhances wellbore stability by preventing fluid invasion into porous formations.

After hydrocarbons are extracted, a by-product called produced water comes up with the oil and gas. This water contains a mixture of oil residues, salts, and fine suspended solids. Before it can be discharged or reused, it must meet strict environmental standards.

Role of PAC:

- PAC helps break oil-water emulsions, separating fine oil droplets and solid contaminants.

- Reduces turbidity and enhances clarity of treated water.

- Functions effectively even in high salinity and temperature conditions.

Result: Treated produced water meets discharge regulations and can be reused for reinjection or industrial purposes, saving costs and protecting ecosystems.

C. Refinery Wastewater Treatment

Refineries generate complex wastewater streams that contain oil, grease, heavy metals, and organic compounds. These must be treated before being released into the environment.

Role of PAC:

- Used as a primary coagulant to remove suspended solids, emulsified oil, and colloidal impurities.

- Enhances performance of biological treatment systems by improving pre-treatment efficiency.

- Reduces the load on secondary filtration or activated carbon stages.

Result: Lower chemical consumption downstream and improved compliance with environmental discharge norms.

D. Cementing and Fracturing Fluids

In cementing and hydraulic fracturing operations, maintaining fluid integrity is essential to ensure proper bonding and pressure control. Certain PAC formulations are used to control fluid loss, improve filtration, and stabilize emulsions.

Role of PAC:

- Improves rheological properties of cement slurries.

- Minimizes leak-off into formations.

- Enhances filtration control in high-pressure zones.

Result: Stronger cement sheaths and more efficient hydraulic fracturing, leading to better production rates.

E. Cooling Tower and Boiler Water Treatment

Refineries and gas processing plants operate large cooling towers and boiler systems. Scale buildup, corrosion, and biological fouling can severely impact heat transfer efficiency.

Role of PAC:

- Acts as a pre-treatment chemical for feed water to reduce suspended solids.

- Prevents scaling and fouling in downstream equipment.

- Improves chemical efficiency of anti-corrosion and anti-scaling agents.

Result: Prolonged equipment life and improved thermal efficiency.

3. Why PAC is Preferred Over Traditional Coagulants

The oil and gas industry used to rely heavily on alum, ferric chloride, and lime-based coagulants. However, these often had drawbacks such as:

- High sludge production

- Corrosive effects on pipelines and storage tanks

- Sensitivity to pH variations

PAC overcomes these challenges through:

- Higher charge density — enabling stronger particle neutralization

- Low sludge generation — reducing disposal costs

- Better pH tolerance — works effectively in acidic and neutral environments

- Non-corrosive nature — safer for equipment

This makes PAC not only technically superior but also economically viable for long-term use in oilfield and refinery systems.

4. Environmental Benefits

Modern oil and gas operations are under increasing scrutiny for sustainability. PAC supports this shift by enabling eco-friendly water management.

- It reduces chemical consumption compared to traditional coagulants.

- Generates non-toxic sludge that’s easier to handle and dispose of.

- Improves water recovery rates, promoting circular water reuse in plants.

Many operators have adopted PAC-based systems as part of their ESG (Environmental, Social, and Governance) commitments.

5. Integration with Other Treatment Chemicals

PAC is often used in combination with other additives like:

- Anionic/cationic polymers – to enhance floc strength and settling.

- Corrosion inhibitors – for additional metal protection in pipelines.

- Antiscalants – for preventing mineral precipitation.

These combinations allow customization of the treatment program for specific crude types, formation waters, or refinery waste streams.

Key Advantages of Polyaluminum Chloride (PAC) in the Oil & Gas Industry

PAC’s performance benefits extend well beyond simple coagulation. It is a multi-functional chemical that brings efficiency, cost-effectiveness, and sustainability into complex oilfield operations.

Let’s break down its main advantages:

A. Superior Coagulation Efficiency

PAC contains pre-hydrolyzed aluminum species that are highly charged. This gives it stronger binding power compared to traditional alum or ferric salts.

- It destabilizes colloids faster.

- Requires a lower dosage to achieve the same or better clarity.

- Works effectively even at varying temperatures and pH levels.

B. Lower Sludge Generation

A common issue with alum and lime coagulants is the heavy sludge they produce, which increases handling and disposal costs. PAC produces less and denser sludge, making dewatering easier.

This translates to:

- Reduced sludge management expenses

- Smaller environmental footprint

- Less downtime for cleaning and disposal operations

C. Wider pH and Temperature Range

PAC performs efficiently in pH ranges from 4.0 to 9.0, allowing it to function in both acidic and neutral systems — something not possible with many traditional coagulants.

Its stability also remains high at elevated temperatures, which is essential in oilfield or refinery applications where water can be hot, saline, or chemically reactive.

D. Improved Filtration and Clarification

PAC enhances filter performance by forming large, compact flocs that are easier to separate mechanically.

This leads to:

- Faster filtration rates

- Lower filter clogging

- Extended filter lifespan

E. Cost Efficiency and Operational Savings

Because of its higher charge density and low sludge yield, PAC often provides the same treatment efficiency with 30–50% less dosage than alum.

When scaled across industrial operations, this results in:

- Significant reduction in chemical cost

- Lower waste handling and disposal charges

- Decreased energy consumption for sludge drying and pumping

F. Compatibility with Other Additives

PAC integrates seamlessly with other treatment chemicals such as:

Polymers (for floc strength)

pH adjusters (for fine-tuning water chemistry)

Biocides (for microbial control)

Antiscalants (for hardness control)

This flexibility allows engineers to create customized water treatment packages suited to specific field conditions.

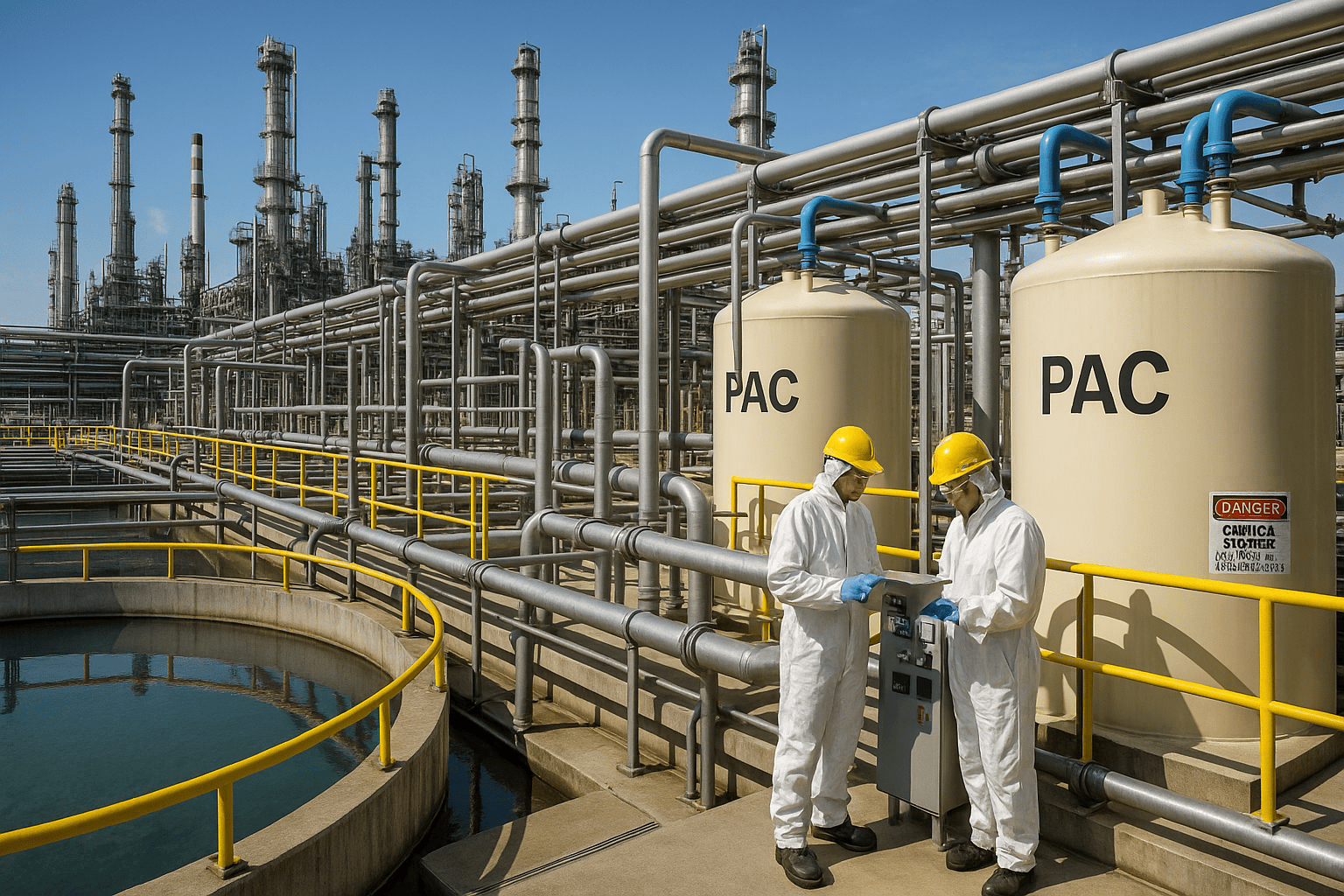

Health and Safety Practices for Handling PAC

While PAC is relatively safer than many traditional coagulants, responsible handling is still crucial in industrial environments. Improper storage or use can result in skin irritation, eye discomfort, or chemical burns.

Here are some essential safety guidelines:

A. Personal Protective Equipment (PPE)

Workers should always wear:

Chemical-resistant gloves

Safety goggles or face shields

Long-sleeved overalls or aprons

Respiratory masks (when handling powdered PAC)

This prevents direct contact or inhalation of fine dust or splashes.

B. Safe Storage Conditions

Store PAC in a cool, dry, and well-ventilated area.

Keep it away from strong alkalis or reactive substances.

Use non-corrosive containers, such as HDPE drums or lined tanks.

Ensure lids are tightly closed to prevent moisture absorption.

C. Handling and Mixing Guidelines

Always add PAC to water, never the reverse — to avoid heat or splash reactions.

Use mechanical agitators for uniform dispersion.

Avoid contamination with other chemicals during transfer.

D. Emergency Procedures

In case of spills or exposure:

Flush the affected area with clean water immediately.

If eye contact occurs, rinse for at least 15 minutes and seek medical attention.

Neutralize spills using absorbent material (e.g., sand or lime).

Proper training and safety data sheets (SDS) should always be made available at the worksite.

Environmental Impact and Sustainability Benefits

Modern oil and gas operations are under increasing scrutiny to minimize environmental impact, and PAC contributes positively in several ways.

A. Reduced Chemical Load

Because PAC has a higher coagulation efficiency, it requires less dosage, resulting in:

Lower overall chemical discharge

Reduced toxicity potential

Smaller carbon footprint from production and transport

B. Enhanced Water Reuse

PAC-treated water can often be reused in drilling, washing, or cooling processes.

This supports circular water management in oilfields — conserving freshwater resources and reducing wastewater discharge volumes.

C. Non-Toxic and Eco-Safe Sludge

Unlike alum-based coagulants, PAC produces neutral or mildly acidic sludge that is easier to neutralize and dispose of safely.

Some sludge can even be repurposed for non-agricultural construction uses, contributing to waste minimization.

D. Compliance with Environmental Regulations

PAC treatment systems help facilities meet global discharge standards like:

EPA (U.S. Environmental Protection Agency)

CPCB (Central Pollution Control Board – India)

EU Water Framework Directive

By ensuring clean effluent quality, PAC enables regulatory compliance and sustainability certification.

E. Reduced Energy Consumption

Efficient clarification and filtration with PAC lead to:

Shorter processing times

Lower pumping requirements

Reduced energy use across treatment systems

This not only cuts operational costs but also aligns with global ESG goals and net-zero initiatives.

Industry Adoption and Trends

PAC is gaining rapid acceptance among:

Oilfield service providers

Refineries and petrochemical plants

EPC companies

Drilling contractors

Waste management specialists

Practical Implementation of PAC in Oil & Gas Operation

Successful use of Polyaluminum Chloride (PAC) requires careful consideration of dosage, mixing conditions, and compatibility with existing systems. When implemented correctly, PAC can dramatically improve treatment efficiency and effluent quality.

Let’s walk through the major steps for smooth and optimized adoption 👇

A. Site Assessment and Water Analysis

Before any chemical treatment is started, engineers conduct a comprehensive water characterization study to identify:

Suspended solids (TSS), turbidity, oil & grease, salinity, and pH

Presence of iron, manganese, or sulfides

Organic matter (COD/BOD) levels

This helps determine PAC type (liquid or powdered) and dosage range, ensuring tailored performance for specific refinery or drilling conditions.

B. Dose Calculation and Jar Testing

Jar tests are essential for establishing the optimal PAC dosage and reaction time.

Prepare several samples of contaminated water.

Add PAC at incremental concentrations (e.g., 10–100 mg/L).

Mix gently and observe floc formation, clarity, and settling speed.

Typically, PAC doses in oil & gas effluents range between 30 – 80 mg/L, depending on pollutant load and water chemistry.

C. Mixing and Contact Time

PAC must be evenly distributed for effective coagulation:

Rapid mixing (30–60 seconds) ensures uniform chemical dispersion.

Followed by slow mixing (10–15 minutes) for floc growth.

Allow a settling time of 30–60 minutes before filtration or flotation.

Efficient mechanical mixers or inline static mixers are recommended in continuous systems.

D. Integration with Other Treatment Stages

PAC functions best when integrated within a multi-stage treatment line:

Stage | Process | PAC Role |

Primary | Oil skimming & equalization | Reduces surface oils and emulsions |

Secondary | Coagulation–flocculation | Key step for solids and oil removal |

Tertiary | Filtration & polishing | Improves clarity and removes residuals |

In refineries, PAC is also paired with anionic polymers or polyacrylamides to strengthen floc structure and accelerate settling.

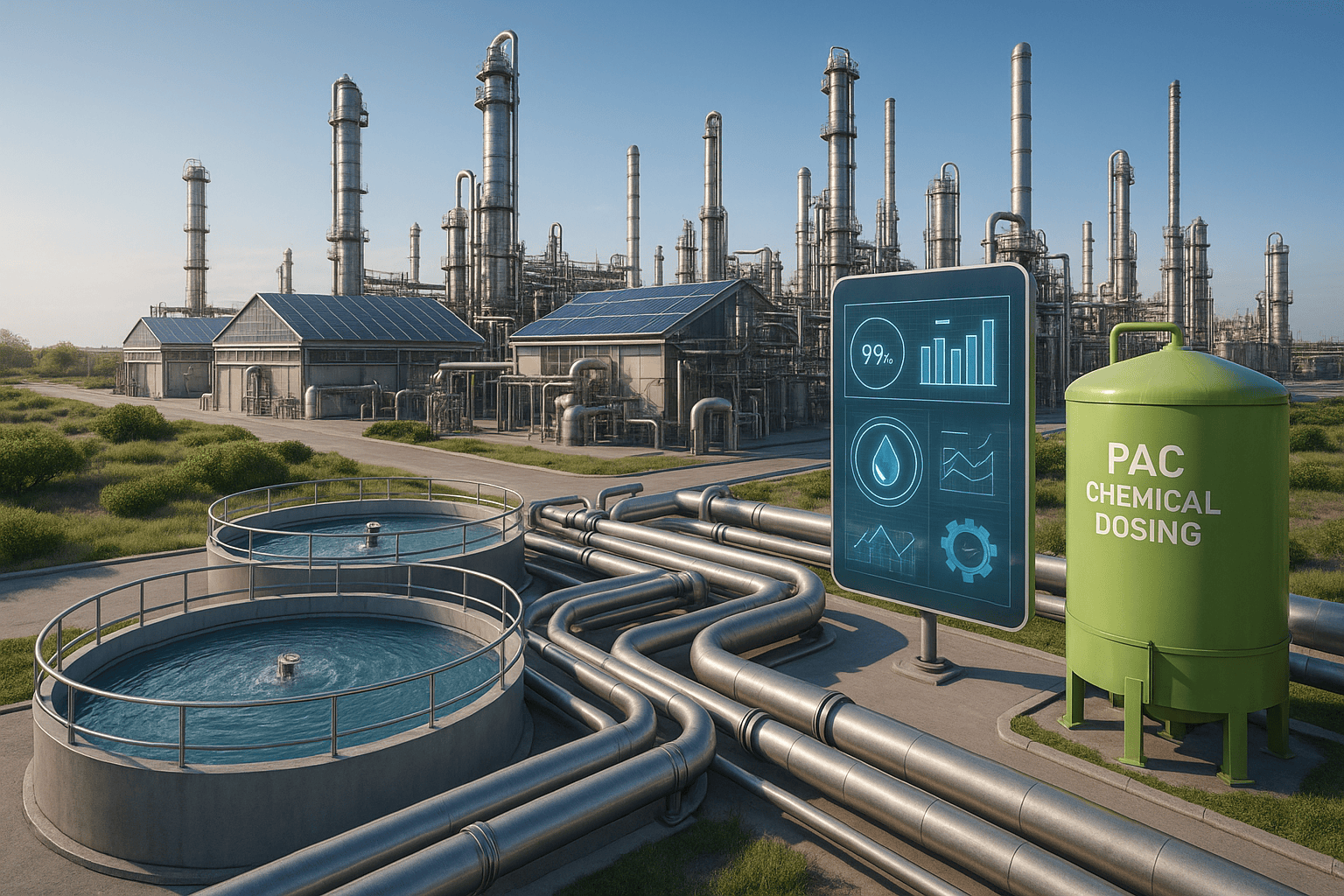

E. Monitoring and Optimization

Regular performance audits should track:

Turbidity & TSS reduction

Chemical oxygen demand (COD) improvement

pH balance and sludge volume

Automation via SCADA or online turbidity sensors can optimize chemical feed, minimize wastage, and maintain consistent effluent quality.

Case Examples of PAC Use in the Oil & Gas Industry

Case 1: Refinery Effluent Clarification (India)

A mid-size Indian refinery faced recurring issues with high turbidity (> 300 NTU) and heavy sludge from alum treatment.

By switching to a 10% PAC solution, the plant achieved:

85% reduction in turbidity (≤ 40 NTU)

40% less chemical usage

50% less sludge generation

This improved compliance with CPCB discharge norms and cut operating costs by ~25%.

Case 2: Drilling Mud Water Treatment (Middle East)

A drilling contractor operating in desert conditions used PAC to recover water from high TDS drilling mud waste.

Results:

Improved settling rate of fine silts and barite particles

Recovered > 70% of water for reuse

Reduced disposal volumes and transport costs significantly

Case 3: Gas Processing Plant Cooling Tower Makeup Water (USA)

PAC was introduced to replace lime softening and alum.

Outcome:

Stable operation across pH 5 – 9

Lower scaling tendency

Enhanced filter performance and reduced biofouling

Future Outlook and Innovations

As water quality challenges intensify in the oil & gas sector, PAC’s role will continue to expand.

Emerging innovations include:

Nano-enhanced PACs – with higher charge density and rapid settling kinetics.

Hybrid coagulant formulations – PAC + organic polymer blends for targeted oil removal.

Smart Dosing Systems – AI-driven feed control based on real-time turbidity data.

Green Manufacturing Methods – producing PAC using industrial by-products like alumina residues.

These developments align with the industry’s shift toward low-carbon, resource-efficient, and zero-liquid discharge (ZLD) operations.

Conclusion

Polyaluminum Chloride (PAC) has emerged as a cornerstone chemical in the oil & gas sector’s effort to achieve cleaner water and sustainable production.

Its versatility — from refinery effluent treatment to drilling fluid recycling — coupled with its eco-friendly profile and cost benefits, make PAC a preferred choice over traditional coagulants.

When implemented correctly with sound monitoring and safety protocols, PAC not only meets environmental regulations but also enhances operational efficiency and long-term ROI for industrial operators.

The future of oil & gas water treatment is smarter, greener, and more sustainable — with PAC at its core.