Introduction

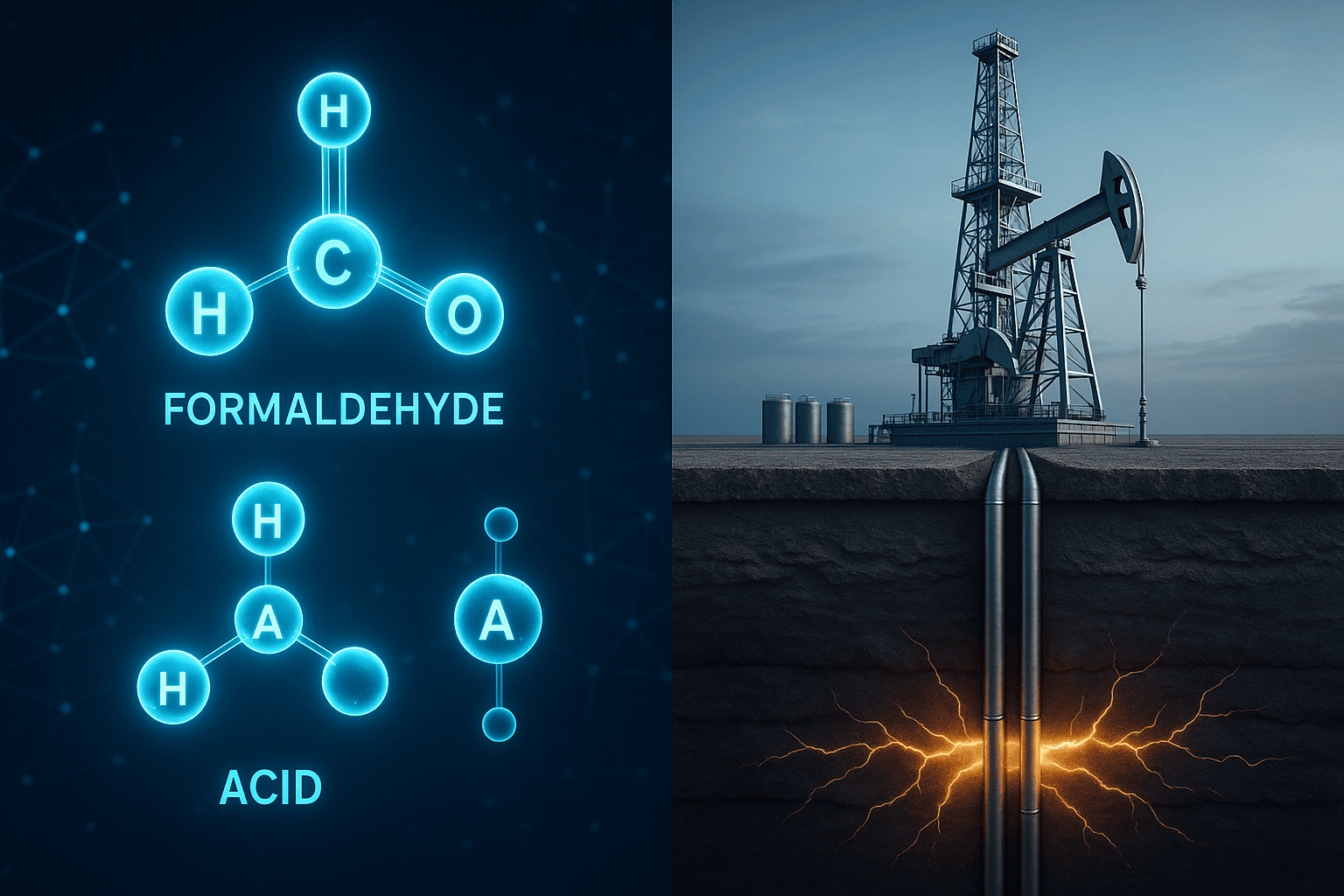

While these names may sound highly technical, their role is simple to understand if we think of them as helpers that keep oilfield operations safe, efficient, and long-lasting. Just as a car needs engine oil and coolant to run smoothly, oilfields depend on chemicals like formalin and acids to function properly.

In this blog, we’ll break down the uses of formalin and acid solutions in oil and gas, explain why they matter, share some examples, and highlight both their benefits and challenges.

A Brief Historical Perspective

Chemicals have been part of the oil and gas industry since the early 20th century. As drilling moved from shallow wells to deeper and more complex formations, operators realized they needed chemical support to fight corrosion, improve production, and handle microbial contamination.

Formalin was first applied in oilfield water treatment in the mid-1900s, when bacterial activity in pipelines caused severe corrosion problems.

Acid solutions were used as early as the 1930s for acidizing treatments in Texas, revolutionizing well stimulation and increasing productivity.

Since then, these substances have become industry staples, though modern practices now emphasize controlled dosages, safety measures, and environmental responsibility.

Understanding Formalin

What is Formalin?

Formalin is a liquid mixture that contains about 37–40% formaldehyde gas dissolved in water, often with a little methanol to keep it stable. It is colorless, has a strong smell, and is highly reactive.

In simple words, formalin is a powerful disinfectant and preservative. If you’ve ever studied biology in school, you might remember specimens stored in glass jars filled with a clear solution—that was often formalin.

In the oil and gas industry, this same property of preserving and protecting is used on a much larger scale.

Industrial Uses of Formalin in Oil & Gas

1. Biocide for Water Treatment

- Prevents growth of harmful microorganisms in drilling and injection water.

- Protects pipelines and storage tanks from bacterial-induced corrosion.

2. Preservation of Drilling Fluids

Stops bacterial spoilage of drilling mud, keeping it stable and effective.

Prevents foul odors and the release of harmful gases.

3. Corrosion Control Support

- By removing bacteria that generate corrosive byproducts, formalin indirectly slows down pipeline corrosion.

4. Gas Sweetening Processes

- Helps reduce sulfur compounds like hydrogen sulfide, making natural gas safer and less corrosive.

5. Preservation During Storage

- Used in stagnant water storage tanks or idle pipelines to prevent bacterial buildup during downtime.

Understanding Acid Solutions

What are Acid Solutions?

An acid solution is simply an acid mixed with water to achieve the desired strength. In oil and gas, the most common acids used are:

Hydrochloric Acid (HCl): Dissolves carbonate rocks, widely used in acidizing.

Sulfuric Acid (H₂SO₄): Strong acid for refining and catalytic processes.

Acetic & Formic Acid: Weaker acids used when a gentler, less corrosive treatment is needed.

Think of acid solutions as cleaning and unlocking agents—they dissolve blockages, clean surfaces, and open up new pathways for oil and gas.

Industrial Uses of Acid Solutions in Oil & Gas

1. Well Stimulation (Acidizing)

Matrix Acidizing: Pumping acid at low pressure to dissolve rock near the wellbore.

Acid Fracturing: Pumping acid at high pressure to fracture rock and then etch channels for hydrocarbon flow.

Both techniques enhance production by creating more flow paths for oil and gas.

2. Scale Removal

- Dissolves hard deposits like calcium carbonate and barium sulfate.

Restores lost productivity in wells and pipelines.

3. Cleaning of Equipment and Pipelines

- Removes rust, scale, and mineral deposits from tanks, refineries, and transport pipelines.

Prevents blockages and mechanical failures.

4. Enhanced Oil Recovery (EOR)

Acids sometimes alter rock properties, improving permeability and fluid mobility.

5. Refining Applications

Sulfuric acid is a key catalyst in alkylation units to produce clean, high-octane fuels.

Real-World Examples

Case 1: North Sea Operations

Formalin was used to control sulfate-reducing bacteria in offshore water injection systems, preventing pipeline corrosion and extending asset life.

Case 2: Middle East Carbonate Fields

Large-scale hydrochloric acid acidizing treatments doubled oil production by dissolving tight carbonate rock formations.Case 3: U.S. Refinery

Sulfuric acid-based alkylation helped boost gasoline quality and meet environmental fuel standards.

Why Formalin and Acid Solutions Are Essential

- Efficiency Boosters → Enhance well productivity and fluid performance.

- Cost Savers → Reduce downtime and expensive repairs.

- Safety Shields → Neutralize harmful bacteria and gases.

- Asset Protectors → Extend pipeline and equipment life.

Challenges & Considerations

- Safety Risks → Both are hazardous, requiring PPE, training, and strict handling.

- Environmental Concerns → Spillage or mismanagement can harm ecosystems.

- Corrosion Side-Effects → Overuse of acids may damage infrastructure.

- Cost of Treatment → High volumes of chemicals increase expenses.

- Regulatory Compliance → Companies must meet local and international environmental standards.

Future Outlook: Safer & Greener Alternatives

Eco-Friendly Biocides → Plant-based or less toxic compounds may replace formalin in some applications.

Chelating Agents & Green Acids → These offer similar results with less environmental risk.

Digital Monitoring → Smart sensors help monitor corrosion and bacterial activity, reducing chemical overuse.

The industry is steadily moving toward a balance: leveraging proven chemicals like formalin and acids while exploring sustainable alternatives.

Conclusion

The oil and gas industry is built on innovation, precision, and the smart use of resources. Formalin and acid solutions may not grab headlines like drilling rigs or offshore platforms, but they are silent enablers of efficiency and safety. From protecting pipelines against bacteria to opening up blocked wells, these chemicals keep the industry moving forward.

As global energy demand continues to grow, the reliance on such chemicals will remain strong—though safer, eco-friendly alternatives are beginning to emerge. The future lies in using these powerful tools responsibly, ensuring both productivity and sustainability.

FAQs

Q1. Why is formalin used in the oil and gas industry?

Formalin acts as a biocide, protecting water systems and drilling fluids from bacteria that cause corrosion and contamination.

Q2. Which acids are most commonly used in oilfield operations?

Hydrochloric acid (HCl), sulfuric acid (H₂SO₄), and weaker acids like acetic and formic acid are commonly used.Q3. What is the difference between acidizing and acid fracturing?

Acidizing: Low-pressure treatment to dissolve rock near the wellbore.

Acid fracturing: High-pressure injection to create fractures, then etch them with acid for long-term flow