Enhanced oil recovery (EOR) is a critical process in the oil and gas industry, focusing on maximizing the extraction of oil from reservoirs. As global energy demand increases and easily accessible oil reserves dwindle, the industry has turned to advanced techniques to boost recovery rates. One such method is the use of surfactants—surface-active agents that reduce the tension between liquids or between a liquid and a solid. This article explores the role of surfactants in EOR, the mechanisms involved, the types of surfactants used, and the challenges and advancements in this field.

The Role of Surfactants in Oil Recovery

The Role of Surfactants in Oil Recovery

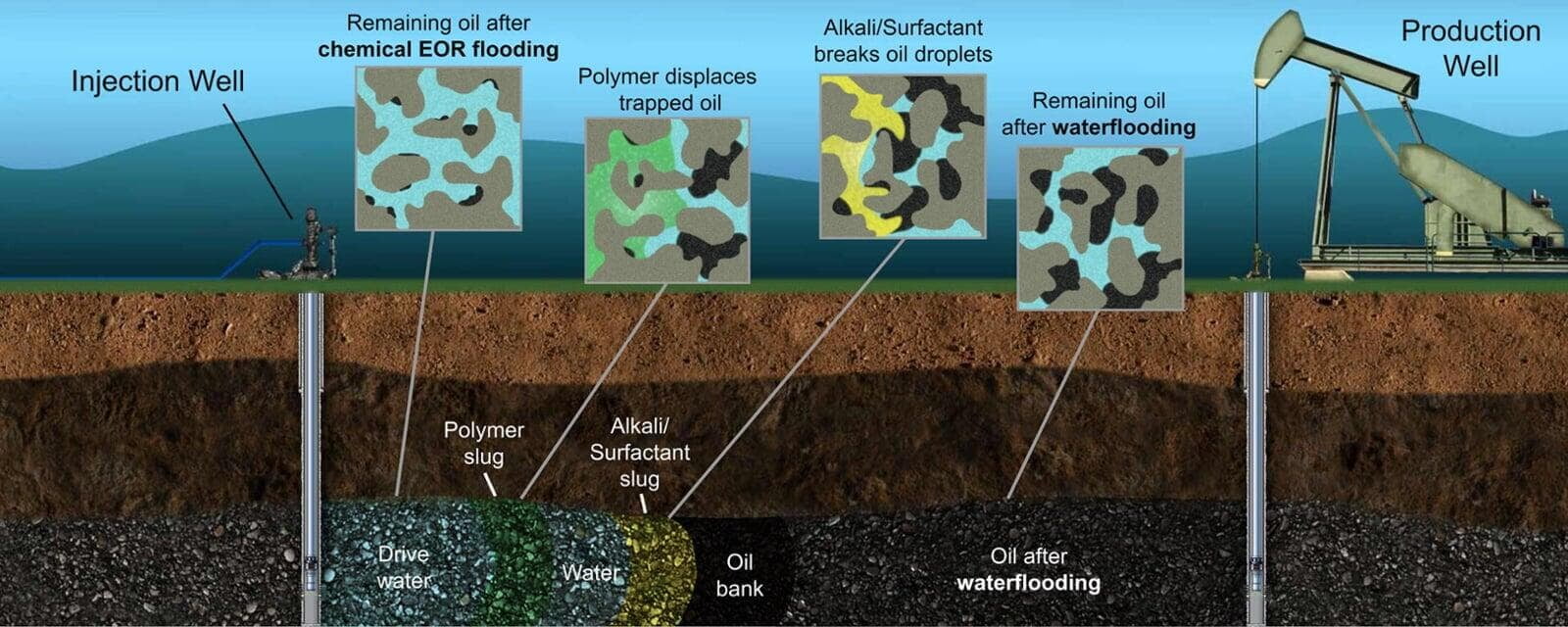

Surfactants play a vital role in enhancing oil recovery by addressing key challenges such as high interfacial tension (IFT) between oil and water, capillary forces, and the wettability of reservoir rocks. These factors often leave significant amounts of oil trapped in rock pores, making it difficult to exceed a recovery rate of 30-50% of original oil in place (OOIP) through primary and secondary recovery methods alone. Surfactant flooding, a leading EOR technique, helps extract this remaining oil by employing the following mechanisms:

1. Reduction of Interfacial Tension (IFT)

Surfactants significantly reduce the IFT between oil and water, which otherwise keeps the oil bound to the rock surface. By lowering the IFT, surfactants facilitate the displacement of oil by injected water, enabling easier mobilization of trapped oil droplets towards production wells.

2. Wettability Alteration

Wettability refers to a solid surface's tendency to prefer one liquid over another. In oil reservoirs, rocks are often oil-wet or mixed-wet, meaning oil clings to the rock surface. Surfactants alter the wettability of reservoir rocks from oil-wet to water-wet, enhancing the displacement of oil by water and improving recovery rates.

3. Microemulsion Formation

Microemulsions are thermodynamically stable mixtures of surfactants, oil, and water with ultra-low IFT, making them highly effective in displacing oil. Depending on surfactant concentration and reservoir conditions, different types of microemulsions—oil-in-water, water-in-oil, or continuous—can form, each with unique properties that enhance oil recovery.

4. Reduction of Capillary Forces

Capillary forces in a reservoir's porous media can trap oil, making it difficult to displace with injected fluids. Surfactants reduce these capillary forces, mobilizing trapped oil and improving flow towards production wells, particularly in highly heterogeneous reservoirs.

Types of Surfactants Used in Oil Recovery

Types of Surfactants Used in Oil Recovery

The selection of surfactants for EOR depends on various factors, including reservoir conditions, temperature, pressure, salinity, and oil type. The primary types of surfactants used in oil recovery are:

1. Anionic Surfactants

Anionic surfactants are widely used in EOR due to their effectiveness in reducing IFT. Their negative charge allows them to adsorb onto positively charged rock surfaces, altering wettability and capillary forces. Common anionic surfactants include sulfonates, carboxylates, and sulfates.

2. Non-Ionic Surfactants

Non-ionic surfactants, which do not carry a charge, are less sensitive to reservoir brine's salinity and hardness. They are often used in combination with anionic surfactants to improve the stability and efficiency of the surfactant solution. Examples include ethoxylated alcohols and alkylphenol ethoxylates.

3. Cationic Surfactants

Cationic surfactants, with a positive charge, interact with negatively charged rock surfaces. Though less commonly used due to higher costs and potential adverse reactions with reservoir brine, they are effective in certain applications, such as carbonate reservoirs.

4. Zwitterionic Surfactants

Zwitterionic surfactants possess both positive and negative charges, offering unique properties for specific reservoir conditions. They balance the advantages of anionic and cationic surfactants, making them valuable in complex reservoir environments.

Challenges of Surfactant-Enhanced Oil Recovery

Challenges of Surfactant-Enhanced Oil Recovery

While surfactants offer significant benefits for EOR, several challenges must be addressed:

1. Cost

The high cost of surfactants, particularly when large quantities are required, is a major barrier to widespread EOR adoption. Additionally, the synthesis and scale-up of specialized surfactants tailored for specific reservoirs can be expensive.

2. Environmental Impact

Environmental concerns regarding the toxicity and biodegradability of surfactants are significant. Although many surfactants are designed to be environmentally friendly, potential contamination of groundwater and ecosystems remains a concern. Ongoing research focuses on developing greener, more sustainable surfactants.

3. Reservoir Conditions

Reservoir conditions, including temperature, pressure, salinity, and the presence of divalent ions like calcium and magnesium, can significantly impact surfactant effectiveness. Careful evaluation of surfactant compatibility with reservoir fluids and rock minerals is crucial to prevent undesirable interactions.

4. Surfactant Retention

Surfactant retention on reservoir rock surfaces through adsorption reduces the effectiveness of surfactant flooding. This retention can increase costs by requiring higher surfactant dosages. Strategies to minimize retention, such as pre-flushing with brine or adding sacrificial agents, further complicate the process.

Advancements in Surfactant-Enhanced Oil Recovery

Despite these challenges, significant advancements have been made in surfactant-enhanced oil recovery, including:

1. Designer Surfactants

Tailored surfactants, designed for specific reservoir conditions, have emerged as a major advancement. These designer surfactants are optimized for reducing IFT, altering wettability, and minimizing retention, even in challenging environments.

2. Nanotechnology

Nanotechnology offers new opportunities for EOR, with nanoparticles acting as surfactant solution stabilizers, microemulsion formation enhancers, and transport promoters. While still in the laboratory phase, this approach shows promise for field applications.

3. Hybrid EOR Methods

Combining surfactant flooding with other EOR techniques, such as polymer flooding or gas injection, often results in synergistic effects, further enhancing oil recovery.

Conclusion

Conclusion

Surfactants are a powerful tool in enhanced oil recovery, especially in reservoirs where conventional methods fall short. By reducing IFT, altering wettability, and forming microemulsions, surfactants can release trapped oil and increase recovery rates. Despite challenges such as cost, environmental impact, and reservoir conditions, ongoing advancements in surfactant technology and EOR techniques hold great promise for the future. As the industry evolves, surfactants will continue to play a central role in maximizing oil recovery and ensuring the responsible extraction of this vital resource.