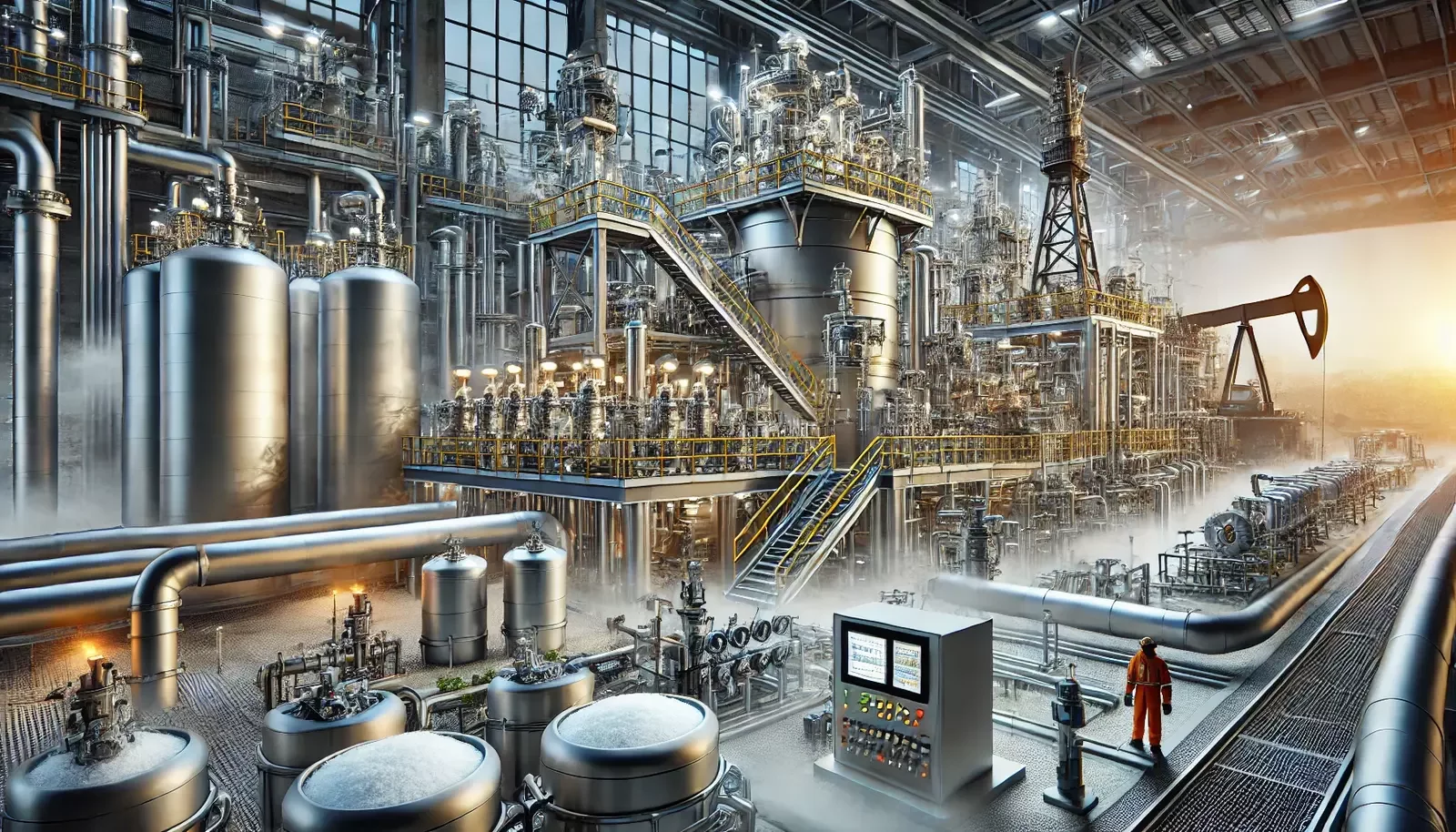

Imagine a high-speed production line grinding to a halt because of unexpected foam buildup, or a drilling operation where uncontrolled bubbles disrupt efficiency, leading to costly downtime. In industries where precision, safety, and uninterrupted operations are paramount, such disruptions are more than just an inconvenience—they can result in substantial financial losses, compromised product quality, and even safety hazards.

This is where liquid defoamers step in as the silent problem-solvers. These powerful chemical additives are designed to control and eliminate unwanted foam, ensuring that industrial processes run efficiently and without disruption. Whether it’s in oil and gas drilling, chemical processing, food and beverage production, or wastewater treatment, defoamers play a crucial role in optimizing performance, protecting equipment, and enhancing overall productivity.

In this blog, we will dive deep into the world of liquid defoamers, exploring how they work, why they are essential across critical industries, and the best practices for their application. From the science behind foam control to real-world industrial applications, we’ll uncover why defoamers are indispensable for maintaining seamless operations. Let’s get started.

Understanding Foam and Its Impact

Ever wondered why foam can be such a persistent challenge in industrial settings? At first glance, foam—essentially a dispersion of gas bubbles within a liquid—might seem like a minor inconvenience. However, its presence in industrial processes can lead to a cascade of serious issues that impact efficiency, safety, and overall productivity. When foam accumulates, it disrupts the performance of critical equipment such as pumps, pipes, and reactors, forcing them to work harder, increasing energy consumption, and causing unexpected downtimes. In systems where precise fluid level measurements are crucial, foam can skew readings, leading to miscalculations that result in costly errors. Industries that rely on stringent quality control, such as food processing, pharmaceuticals, and paint manufacturing, often struggle with foam trapping unwanted air, leading to inconsistencies in texture, formulation defects, and compromised end products. In high-pressure environments like oil and gas drilling, excessive foam buildup can interfere with well control, increasing the risk of hazardous situations. Ultimately, foam is more than just an aesthetic or operational nuisance—it directly impacts productivity, inflates operational costs, and can pose significant safety threats. This is why industries across the board invest in effective defoaming solutions to mitigate risks, optimize efficiency, and maintain smooth operations.

What are Liquid Defoamers?

Liquid defoamers are chemical additives specifically formulated to control, reduce, or eliminate foam in industrial processes. Unlike antifoams, which prevent foam formation before it starts, defoamers work by breaking down existing foam, ensuring smooth and efficient operations. These compounds are widely used across industries such as oil and gas, chemical processing, wastewater treatment, food and beverage production, and pharmaceuticals, where excessive foam can disrupt equipment performance, compromise product quality, and increase operational costs.

How Do Liquid Defoamers Work?

Liquid defoamers function by destabilizing the gas-liquid interface of foam bubbles, causing them to collapse and dissipate. They typically contain hydrophobic particles and surface-active agents that reduce surface tension, weaken bubble walls, and accelerate foam breakdown. Some common mechanisms include:

Spreading Action: Defoamers spread rapidly across the foam surface, disrupting bubble stability and causing them to burst.

Displacement of Air: By lowering the surface tension, defoamers force trapped air out of the liquid phase, reducing foam volume.

Oil-Based Mechanisms: Certain defoamers contain oils that destabilize foam films, making them more prone to rupture.

Benefits of Using Liquid Defoamers in the Oil and Gas Industry

Liquid defoamers play a crucial role in managing foam-related challenges in oil and gas operations. By effectively controlling and eliminating foam, they help maintain operational efficiency, reduce costs, and ensure compliance with environmental regulations. Below is a detailed explanation of their key benefits:

1. Enhanced Drilling Efficiency

Foam formation in drilling fluids can cause significant disruptions, leading to poor fluid circulation, decreased drilling speed, and increased downtime. Liquid defoamers are specifically designed to break down foam quickly, ensuring smooth drilling operations. By stabilizing the drilling mud and preventing foam-induced blockages, defoamers enhance pressure control and improve the efficiency of the entire drilling process. This leads to better wellbore stability and minimizes non-productive time (NPT), allowing operations to run seamlessly.

2. Improved Separation and Processing

In oil and gas production, gas-liquid separation is a critical process. Excessive foam in separators can cause overflow, reduce the efficiency of separation units, and lead to product losses. Liquid defoamers improve the separation of gas, oil, and water by breaking down foam layers, allowing for better phase separation. This results in increased hydrocarbon recovery, reduced equipment wear, and optimized processing performance. Additionally, foam reduction enhances heat exchanger and pipeline efficiency, ensuring smooth transportation and refining of crude oil.

3. Cost Savings and Energy Efficiency

Uncontrolled foam formation can cause excessive strain on pumps, compressors, and other processing equipment, leading to increased power consumption and frequent maintenance. Liquid defoamers help prevent these issues by reducing foam buildup, which minimizes pressure drops, prevents cavitation, and ensures optimal equipment performance. As a result, energy usage is reduced, and maintenance costs are lowered due to decreased wear and tear. This translates into significant cost savings for oil and gas companies over time.

4. Compliance with Environmental Regulations

Oil and gas operations generate wastewater that often contains foaming agents, making it difficult to treat and discharge safely. In wastewater treatment facilities, uncontrolled foam can lead to operational challenges and environmental compliance issues. Liquid defoamers assist in breaking down foam quickly, preventing spills, and ensuring efficient wastewater processing. By reducing the risk of discharge violations and improving water treatment efficiency, defoamers help companies meet regulatory standards set by environmental agencies, ensuring safe and sustainable operations.

The use of liquid defoamers in the oil and gas industry provides numerous operational benefits, from enhancing drilling efficiency and optimizing production processes to reducing costs and ensuring regulatory compliance. By effectively controlling foam, these chemical additives play a vital role in maintaining smooth and efficient oilfield operations, ultimately improving productivity and profitability

Choosing the Right Liquid Defoamer for Oil and Gas Operations

Selecting an appropriate liquid defoamer is crucial for maintaining operational efficiency in oil and gas processes. The right choice depends on several factors, including chemical composition, operating conditions, and application methods. Below is a detailed breakdown of the key considerations when selecting a defoamer:

1. Chemical Compatibility

One of the most important factors when choosing a defoamer is its compatibility with drilling fluids, production chemicals, and process conditions. Oil and gas operations involve a variety of chemical additives, such as surfactants, corrosion inhibitors, and lubricants. A defoamer must be chemically stable and non-reactive with these substances to prevent unwanted side effects like emulsification, residue formation, or reduced efficiency of other treatment chemicals.

Silicone-based defoamers: Highly effective at reducing foam but may interfere with downstream processing in certain refining operations.

Oil-based defoamers: Work well in crude oil processing but need to be compatible with specific hydrocarbons.

Water-based defoamers: Often used in water treatment but may not be effective in high-viscosity systems.

Selecting a defoamer with the right chemical composition ensures that it integrates seamlessly with existing fluids, maintaining system stability and efficiency.

2. Effectiveness at Different Temperatures and Pressures

Oil and gas operations span a wide range of temperatures and pressures, from deep-sea drilling environments with extreme cold and high pressure to onshore fields with scorching heat. Defoamers must be able to withstand these varying conditions without degrading or losing effectiveness.

High-temperature resistance: In refinery and drilling operations, temperatures can exceed 200°C. A defoamer that breaks down at these temperatures will be ineffective.

High-pressure performance: Deepwater drilling and high-pressure pipelines require defoamers that can function under extreme pressure without altering their chemical properties.

Low-temperature applications: In Arctic or cold-weather environments, defoamers must remain liquid and effective without freezing or becoming too viscous.

Choosing a defoamer that maintains consistent performance across different operating environments ensures uninterrupted processing and foam control.

3. Application Method

The method of applying a defoamer also impacts its effectiveness and ease of use. Different application techniques are suitable for different processes, and selecting the right one can optimize efficiency and cost-effectiveness.

Direct Injection

Some defoamers are designed to be injected directly into drilling muds, production fluids, or wastewater systems using automated injection pumps.

This method provides continuous foam control and is ideal for processes requiring real-time foam suppression.

It is commonly used in gas-oil separation units (GOSUs), drilling fluid systems, and cooling towers.

Dilution Before Application

Certain defoamers require pre-dilution with water or another solvent before being added to the system.

This is useful in processes where uniform distribution is essential, such as wastewater treatment plants and low-viscosity systems.

Proper dilution prevents overdosing, which can lead to unnecessary chemical costs and potential residue issues.

Batch Treatment

In some cases, defoamers are added in batches at specific intervals rather than continuously.

This is beneficial when foam formation is seasonal or intermittent, such as in some crude oil storage and transport operations.

The right application method depends on the process requirements, equipment capabilities, and foam formation patterns, ensuring that the defoamer is used efficiently with minimal waste.

Conclusion

Liquid defoamers play an indispensable role in optimizing productivity, enhancing efficiency, and reducing operational costs in the oil and gas industry. By effectively managing foam-related challenges in drilling, processing, and wastewater treatment, they contribute to smoother operations and improved profitability. Choosing the right defoamer tailored to specific industry needs is crucial for maximizing its benefits.