Introduction: Why Biocides Matter More Than Ever in Oilfield Operations

Microbial contamination is one of the most underestimated risks in oil and gas operations. While corrosion, scaling, and formation damage are widely discussed, the role of microorganisms in accelerating these problems is often overlooked until failures occur. From drilling and completion fluids to production systems and pipelines, microbial growth can compromise operational efficiency, asset integrity, and safety.

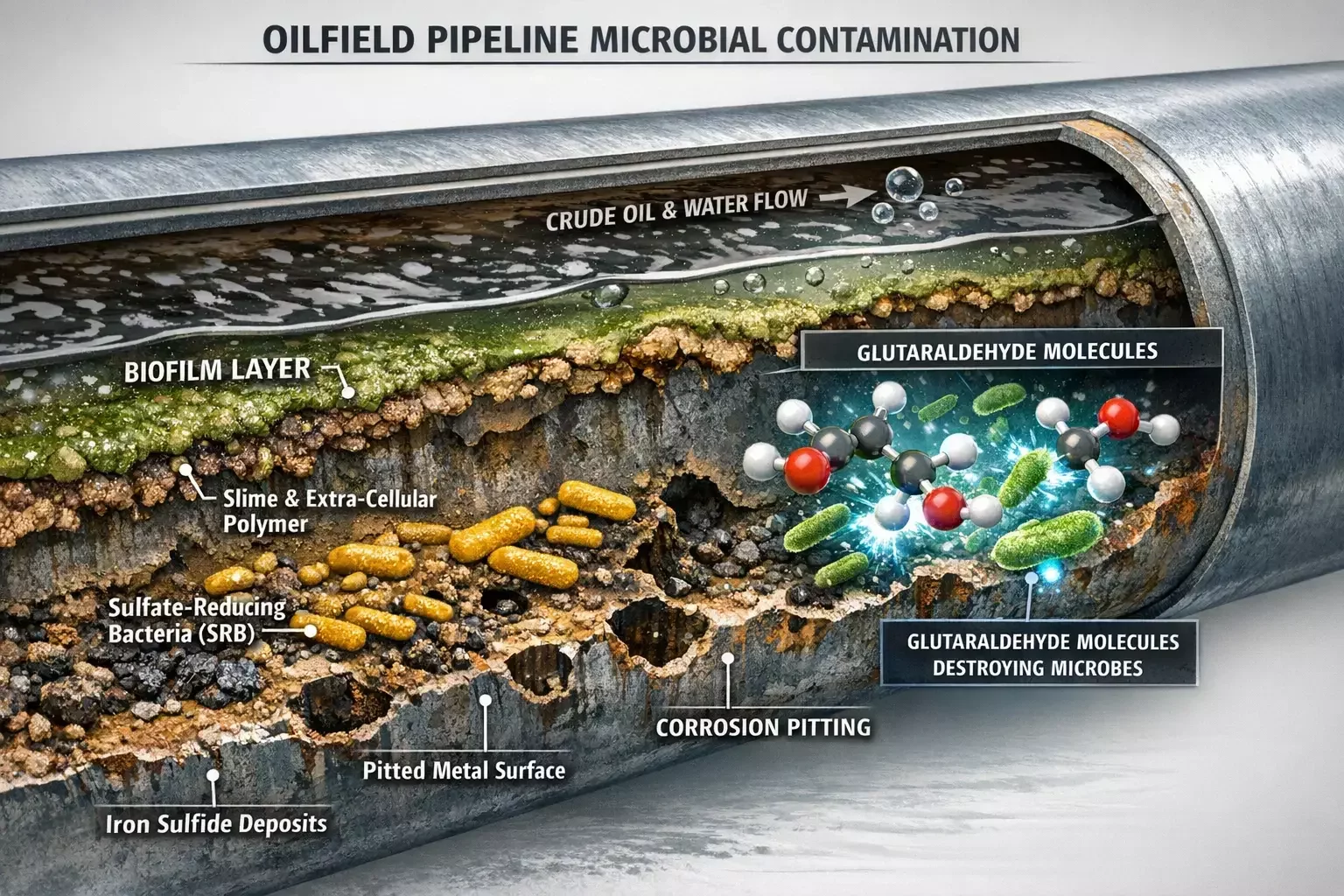

In oilfield environments, water is almost always present—whether as formation water, injection water, or produced water. Wherever water exists, microorganisms can thrive. These microbes form biofilms, generate corrosive by-products, plug pores, degrade chemicals, and interfere with production processes. Left untreated, microbial activity can lead to severe corrosion, flow restrictions, souring, and increased operational costs.

This is where biocides become critical. Among the wide range of antimicrobial chemicals used in the oil and gas industry, glutaraldehyde has established itself as one of the most reliable and high-performance biocides. Its effectiveness across diverse operating conditions, compatibility with oilfield systems, and rapid action make it a preferred choice in many upstream and midstream applications.

This blog explores glutaraldehyde in depth—what it is, how it works, where it is used, and why it continues to play a vital role in modern oilfield operations.

What Is Glutaraldehyde? A Simple Chemical Explained Clearly

Glutaraldehyde is an organic compound belonging to the aldehyde family. Chemically, it is a dialdehyde, meaning it contains two aldehyde functional groups. In industrial applications, glutaraldehyde is commonly supplied as an aqueous solution, typically in concentrations ranging from 25% to 50%.

Unlike some oxidizing biocides that rely on aggressive chemical reactions, glutaraldehyde functions as a non-oxidizing biocide. This distinction is important in oilfield systems, where compatibility with metals, elastomers, and process chemicals is critical. Non-oxidizing biocides tend to be more selective, stable, and controllable in complex chemical environments.

Glutaraldehyde is valued for its broad-spectrum antimicrobial activity. It is effective against:

Sulfate-reducing bacteria (SRB)

Acid-producing bacteria (APB)

Iron bacteria

Slime-forming bacteria

Fungi and algae (to a lesser extent)

This versatility makes it suitable for a wide range of oilfield applications, from drilling fluids to long-term production systems.

Why Microbial Control Is Critical in Oilfield Environments

Oilfield systems create ideal conditions for microbial growth. Warm temperatures, nutrient availability, and stagnant or slow-moving fluids encourage bacteria to multiply rapidly. Once established, microbes do not simply float freely; they attach to surfaces and form biofilms—a protective matrix that shields them from chemical treatment.

Microbial activity in oil and gas operations can lead to several serious issues:

Microbiologically Influenced Corrosion (MIC)

Certain bacteria, especially sulfate-reducing bacteria, produce hydrogen sulfide and organic acids as metabolic by-products. These compounds aggressively attack carbon steel and other metals, leading to localized pitting corrosion that can cause unexpected failures.

Reservoir and Formation Damage

Microbial growth can plug pore throats in the reservoir, reducing permeability and restricting fluid flow. This directly impacts production rates and recovery efficiency.

Souring of Reservoirs and Production Streams

Hydrogen sulfide generated by microbial activity creates sour conditions, increasing safety risks, corrosion rates, and treatment costs.

Operational Disruptions

Biofilms can foul filters, block injection lines, interfere with sensors, and reduce the effectiveness of other treatment chemicals.

Given these risks, effective biocide programs are not optional—they are essential for maintaining safe, efficient, and economically viable operations.

How Glutaraldehyde Works as a Biocide

Glutaraldehyde’s effectiveness lies in its ability to disrupt essential biological functions at the cellular level. Once introduced into a contaminated system, glutaraldehyde penetrates microbial cell walls and reacts with proteins and enzymes that are critical for survival.

Specifically, glutaraldehyde forms cross-links with amino groups in proteins. This cross-linking:

Inactivates enzymes required for metabolism

Disrupts cell membrane integrity

Prevents replication and cellular repair mechanisms

As a result, microorganisms are rapidly killed or rendered inactive. Unlike some biocides that only affect free-floating bacteria, glutaraldehyde is also effective against bacteria embedded within biofilms, making it particularly valuable in oilfield systems where biofilm formation is common.

Another advantage is that glutaraldehyde maintains its biocidal activity over a broad pH range and remains stable under varying temperature and salinity conditions, which are typical of oilfield environments.

Key Advantages of Glutaraldehyde in Oilfield Operations

Glutaraldehyde has remained widely used despite the emergence of newer biocides because it offers a balanced combination of performance, reliability, and adaptability.

One of its primary strengths is rapid kill efficiency. Glutaraldehyde acts quickly, allowing operators to control microbial populations before they cause measurable damage. This is particularly important during drilling, completion, and startup phases when microbial growth can accelerate.

Another advantage is compatibility. Glutaraldehyde does not aggressively oxidize metals or degrade most oilfield elastomers when used at recommended dosages. This makes it suitable for systems where material integrity is critical.

Glutaraldehyde is also versatile. It can be applied in batch treatments, continuous injection programs, or shock dosing strategies depending on operational requirements. Its effectiveness across different fluid systems—water-based, oil-based, and mixed-phase—adds to its flexibility.

Finally, glutaraldehyde is predictable and well-understood. Decades of oilfield use have established clear guidelines for dosage, handling, and performance expectations, reducing uncertainty for operators.

Where Glutaraldehyde Fits in the Oilfield Lifecycle

Glutaraldehyde is not limited to a single phase of oil and gas operations. Instead, it is used throughout the lifecycle of a well and associated surface facilities.

During drilling and completion, glutaraldehyde helps control bacterial contamination in drilling fluids and completion brines, protecting both equipment and formations.

In production systems, it is commonly injected into flowlines, separators, and produced water systems to prevent biofouling and corrosion.

For water injection and enhanced recovery operations, glutaraldehyde helps maintain injectivity by preventing microbial plugging and reservoir souring.

Its ability to perform across these varied environments makes it a cornerstone biocide in oilfield chemical programs.

Glutaraldehyde in Drilling Fluids: Controlling Bacteria Before Problems Begin

Drilling fluids are one of the first points where microbial contamination can enter an oilfield system. These fluids often contain water, organic polymers, starches, and other additives that can serve as nutrients for bacteria. When drilling fluids are reused, stored, or circulated for extended periods, bacterial growth can escalate rapidly.

Uncontrolled microbial activity in drilling fluids can degrade polymers, alter rheology, generate foul odors, and contribute to early-stage corrosion of drilling equipment. More importantly, bacteria can be carried downhole, introducing microbial contamination directly into the formation.

Glutaraldehyde is commonly added to drilling fluids as a preventative biocide. Its role is not only to kill existing bacteria but also to suppress future microbial growth during prolonged drilling campaigns. Because glutaraldehyde remains effective across a wide range of salinity and temperature conditions, it performs reliably in both onshore and offshore drilling environments.

By controlling bacteria at this early stage, glutaraldehyde helps preserve drilling fluid properties, protects drill strings and surface equipment, and reduces the likelihood of downstream microbial problems later in the well’s life.

Use in Completion Fluids: Protecting the Well During Critical Transition Phases

Completion fluids represent a sensitive phase in well construction. These fluids are often clear brines designed to protect the reservoir while allowing controlled access to the formation. Any contamination introduced during completion can have long-term consequences for productivity and integrity.

Microorganisms present in completion fluids can colonize tubulars, packers, and near-wellbore formations. Once the well is placed on production, these microbes may accelerate corrosion, contribute to souring, or interfere with flow.

Glutaraldehyde is widely used in completion fluids to ensure microbial control during this transition period. Its non-oxidizing nature allows it to be used without significantly affecting fluid clarity, density, or compatibility with completion hardware. It also minimizes the risk of elastomer degradation, which is critical for packers, seals, and valves.

In many cases, glutaraldehyde is applied as a batch treatment prior to completion or as part of a circulating program to ensure all internal surfaces are protected. This proactive approach reduces post-completion remediation costs and enhances long-term well reliability.

Production Systems: Preventing Biofouling and MIC During Steady-State Operations

Once a well enters production, microbial risks do not disappear—they often increase. Produced fluids typically contain water, hydrocarbons, dissolved gases, and trace nutrients that support microbial growth. Flowlines, separators, and storage tanks provide surfaces where biofilms can form and persist.

Microbiologically influenced corrosion (MIC) is one of the most damaging outcomes of uncontrolled microbial growth in production systems. Unlike uniform corrosion, MIC tends to be localized and aggressive, leading to unexpected failures in pipelines and equipment.

Glutaraldehyde plays a key role in production chemistry programs aimed at controlling these risks. It is commonly injected into flowlines, headers, and production equipment either continuously at low dosages or periodically as a shock treatment. Its ability to penetrate biofilms and inactivate embedded bacteria makes it especially effective where surface fouling has already begun.

By maintaining microbial control, glutaraldehyde helps extend the life of production assets, reduce maintenance frequency, and ensure consistent flow performance.

Water Injection and Enhanced Oil Recovery (EOR) Systems

Water injection systems are particularly vulnerable to microbial contamination because they involve large volumes of water, often sourced from surface or produced water streams. These systems operate continuously and under conditions that encourage biofilm formation in pipelines, pumps, and injection wells.

If microbial growth is not controlled, injection systems can suffer from reduced injectivity due to biofilm plugging. In addition, sulfate-reducing bacteria introduced into the reservoir can generate hydrogen sulfide, leading to souring and accelerated corrosion.

Glutaraldehyde is frequently used in water injection systems as part of a comprehensive microbial management strategy. It may be applied at water treatment facilities, injection headers, or directly at the wellhead. Its broad-spectrum effectiveness allows operators to control diverse microbial populations without the need for multiple biocides.

In enhanced oil recovery operations, where precise reservoir conditions are critical, glutaraldehyde helps preserve injection efficiency and protects both surface and subsurface infrastructure.

Pipeline and Storage Applications: Long-Term Asset Protection

Pipelines and storage tanks represent long-term investments in oil and gas operations. When fluids remain stagnant or flow slowly, microbial growth can accelerate, particularly in low points, dead legs, and storage vessels.

Biofilms formed inside pipelines can trap corrosive species, creating localized corrosion cells that weaken the pipe wall. Over time, this can result in leaks, environmental incidents, and costly shutdowns.

Glutaraldehyde is used in pipeline preservation programs to control microbial growth during both active service and idle periods. In storage tanks, it helps prevent sludge formation and microbial degradation of stored fluids.

Its stability and predictable performance make it suitable for long-term preservation treatments, especially during commissioning, shutdowns, or seasonal operations.

Compatibility with Other Oilfield Chemicals

One of the reasons glutaraldehyde remains widely used is its compatibility with many other oilfield chemicals. It can be integrated into programs that include corrosion inhibitors, scale inhibitors, demulsifiers, and oxygen scavengers without significant adverse interactions.

This compatibility allows operators to design integrated chemical treatment programs rather than isolated solutions. When applied correctly, glutaraldehyde enhances overall system reliability without complicating chemical management.

Why Application Strategy Matters

While glutaraldehyde is a powerful biocide, its effectiveness depends heavily on how it is applied. Dosage, contact time, injection point, and system conditions all influence performance. Overuse can lead to unnecessary chemical costs, while under-dosing may allow resistant microbial populations to persist.

This is why experienced suppliers and technical partners play an important role in designing glutaraldehyde treatment programs tailored to specific field conditions. Proper application ensures microbial control while maintaining safety, compliance, and cost efficiency.

Balancing Performance and Safety in Oilfield Biocide Programs

Glutaraldehyde’s effectiveness as a biocide is precisely what makes it both valuable and sensitive to handling. In oilfield operations, chemicals are rarely judged on performance alone; they must also align with safety protocols, environmental regulations, and operational efficiency goals. Glutaraldehyde sits at this intersection, requiring disciplined management to deliver value without introducing unnecessary risk.

Unlike oxidizing biocides that can react aggressively with metals or other treatment chemicals, glutaraldehyde provides controlled microbial kill rates. This predictability allows operators to design treatment programs that maintain system hygiene while minimizing chemical shock to equipment and personnel. However, achieving this balance depends on well-defined operational controls and trained handling practices.

Safe Handling and Storage Practices in Oilfield Environments

Glutaraldehyde is typically supplied as an aqueous solution at standardized concentrations. While it is stable under normal conditions, improper handling can expose workers to health risks such as skin irritation, respiratory discomfort, or eye exposure.

In oilfield settings, safe handling begins with proper storage. Containers should be kept in well-ventilated, shaded areas away from direct heat sources. Storage locations are usually designated chemical zones with secondary containment to prevent accidental spills from spreading into soil or drainage systems.

Personnel responsible for handling glutaraldehyde must be equipped with appropriate personal protective equipment, including chemical-resistant gloves, eye protection, and, where required, respiratory protection. Clear labeling, safety data sheets, and training programs ensure that workers understand both the hazards and correct response procedures.

By embedding these practices into standard operating procedures, oilfield operators reduce incident risks while maintaining uninterrupted chemical treatment programs.

Optimizing Dosage for Maximum Efficiency

One of the most common misconceptions surrounding biocides is that higher dosages automatically lead to better control. In reality, excessive dosing of glutaraldehyde can increase operational costs and create unnecessary chemical exposure without improving microbial control.

Effective glutaraldehyde programs rely on accurate system assessment. Factors such as water chemistry, temperature, residence time, microbial load, and flow dynamics must be evaluated before selecting dosage levels. In many cases, periodic shock dosing combined with low-level maintenance treatment delivers better long-term results than continuous high dosing.

Monitoring microbial activity through field testing allows operators to fine-tune treatment frequency and dosage. This data-driven approach ensures that glutaraldehyde remains effective while supporting cost optimization and chemical stewardship goals.

Environmental Responsibility and Regulatory Compliance

Environmental compliance has become a defining factor in oil and gas chemical selection. Regulatory authorities increasingly scrutinize the discharge, handling, and disposal of biocides due to their potential ecological impact.

Glutaraldehyde is subject to regional regulations governing its use, transportation, and disposal. Operators must ensure that residual concentrations in discharged fluids remain within permitted limits. In many cases, produced water treated with glutaraldehyde undergoes further processing or dilution before disposal or reinjection.

Compared to some alternative biocides, glutaraldehyde offers advantages in terms of controllability and degradation. Under appropriate conditions, it breaks down into less harmful byproducts, reducing long-term environmental persistence. This characteristic supports its continued use in fields where regulatory oversight is strict and environmental impact assessments are mandatory.

By aligning chemical programs with environmental guidelines, operators protect both their licenses to operate and their reputation with regulators and local communities.

Reducing Operational Downtime Through Preventive Biocide Use

Microbial contamination often manifests gradually, but its consequences can be sudden and costly. Pipeline failures, injector plugging, souring events, and equipment corrosion can halt operations with little warning.

Preventive use of glutaraldehyde plays a critical role in reducing unplanned downtime. Instead of reacting to microbial problems after they escalate, proactive biocide programs keep systems within controlled operating conditions.

This preventive approach supports smoother operations, predictable maintenance schedules, and extended equipment life. For facilities operating under tight production targets, such stability translates directly into improved asset utilization and economic performance.

Integration with Digital Monitoring and Modern Field Management

As oilfields become more data-driven, chemical management is increasingly integrated with digital monitoring systems. Microbial activity, corrosion rates, and fluid quality parameters are tracked in near real time, allowing operators to adjust treatment strategies proactively.

Glutaraldehyde fits well into this modern operational model. Its performance can be correlated with monitoring data to refine dosing strategies and identify emerging risks early. This integration supports smarter decision-making and aligns with broader digital oilfield initiatives focused on efficiency and reliability.

Building Long-Term Value Through Responsible Chemical Use

The value of glutaraldehyde extends beyond immediate microbial control. When applied responsibly, it becomes part of a broader asset integrity strategy that supports safety, compliance, and sustainability.

Oilfield operators increasingly view chemicals not as isolated consumables but as tools that influence long-term performance. Glutaraldehyde, when managed correctly, contributes to lower lifecycle costs, reduced failure rates, and improved environmental outcomes.

Conclusion: Why Glutaraldehyde Remains a Cornerstone Oilfield Biocide

Glutaraldehyde has earned its place as one of the most trusted biocides in oilfield operations because it consistently delivers where microbial control directly impacts safety, integrity, and production reliability. From controlling sulfate-reducing bacteria in produced water systems to protecting pipelines, tanks, and injection wells from biofouling and microbiologically influenced corrosion, its role extends across upstream, midstream, and downstream operations.

What sets glutaraldehyde apart is its balance of performance and controllability. It offers broad-spectrum microbial kill efficiency without the aggressive reactivity associated with oxidizing biocides, making it suitable for complex oilfield systems containing sensitive metallurgy, elastomers, and mixed chemical treatments. This predictability allows operators to design targeted programs that control microbial growth while minimizing operational disruptions.

Equally important is how glutaraldehyde fits into modern oilfield priorities. With increasing regulatory oversight, environmental accountability, and cost pressures, operators require solutions that are effective, manageable, and compliant. When applied correctly—supported by monitoring, proper handling practices, and optimized dosing—glutaraldehyde supports long-term asset integrity, reduced downtime, and improved production continuity.

As oilfields evolve toward more data-driven and sustainability-focused operations, glutaraldehyde continues to adapt. Its compatibility with digital monitoring, tailored formulations, and integrated chemical management programs ensures that it remains a relevant and high-value solution in both mature fields and new developments.

In short, glutaraldehyde is not just a biocide—it is a strategic tool in maintaining the health, safety, and efficiency of oilfield operations.

Frequently Asked Questions (FAQs)

1. Why is glutaraldehyde preferred over oxidizing biocides in oilfield systems?

Glutaraldehyde is often preferred because it provides controlled, non-oxidizing microbial control. Unlike oxidizing biocides, it does not aggressively react with metals or other treatment chemicals, reducing the risk of equipment damage and chemical incompatibility. This makes it particularly suitable for closed systems, pipelines, and injection networks.

2. Can glutaraldehyde be used in both water-based and oil-based systems?

Yes, glutaraldehyde is effective in both water-based and mixed-phase systems. It is widely used in produced water treatment, drilling fluids, completion fluids, and injection water systems, where microbial growth poses operational or integrity risks.

3. How does glutaraldehyde help prevent corrosion in oilfield equipment?

Glutaraldehyde controls bacteria that produce corrosive by-products such as hydrogen sulphide and organic acids. By reducing microbial populations, it indirectly limits microbiologically influenced corrosion (MIC), helping protect pipelines, tanks, and downhole equipment from premature failure.

4. Is glutaraldehyde safe to use in oilfield operations?

When handled and applied according to recommended safety guidelines, glutaraldehyde can be used safely. Proper storage, personal protective equipment, training, and spill management protocols are essential to minimize exposure risks and ensure worker safety.

5. How is the correct dosage of glutaraldehyde determined?

Dosage depends on several factors, including microbial load, system volume, temperature, residence time, and water chemistry. Field testing and monitoring are typically used to optimize dosage, ensuring effective microbial control without excessive chemical use.

6. Does glutaraldehyde pose environmental concerns?

Like all biocides, glutaraldehyde must be managed responsibly. Regulatory limits govern its discharge and disposal. Under controlled conditions, it degrades into less harmful compounds, making it manageable within compliant environmental programs when applied correctly.

7. Is glutaraldehyde still relevant with newer biocide technologies available?

Yes. While alternative and hybrid biocides continue to emerge, glutaraldehyde remains widely used due to its proven performance, adaptability, and cost-effectiveness. Many modern treatment programs still rely on it as a primary or complementary biocide.