Water treatment is a critical process that ensures the availability of safe and clean water for consumption, industrial use, and environmental protection. It involves the removal of impurities, contaminants, and harmful microorganisms to meet safety standards and preserve ecosystems. Among the chemicals employed in water treatment, ferric chloride solution plays a significant role. This versatile coagulant is widely used for its effectiveness in removing suspended particles, organic matter, and even heavy metals from water. By facilitating the aggregation of fine particles into larger clumps, ferric chloride simplifies their removal during filtration or sedimentation. Its application extends to municipal water systems, industrial wastewater management, and sewage treatment, underscoring its importance in safeguarding public health and reducing environmental pollution.

About Ferric Chloride:

About Ferric Chloride:

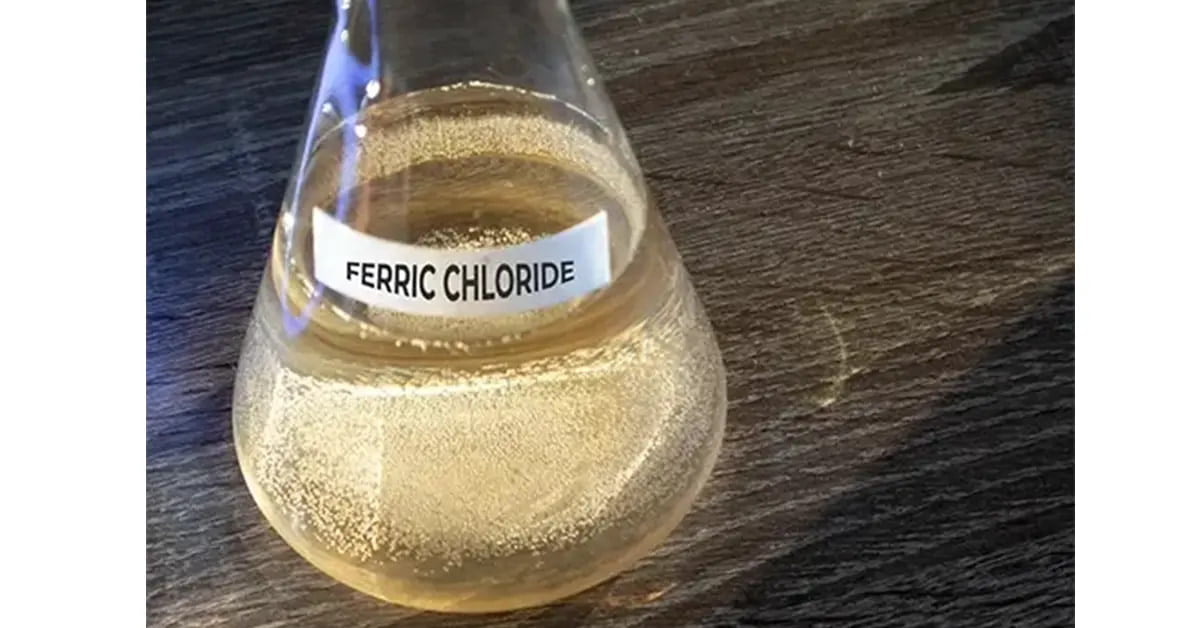

Ferric chloride is a vital inorganic compound widely used in water purification processes for its effective coagulation and flocculation properties. Typically appearing as a yellowish-brown solid or solution, it is highly soluble in water, making it convenient for large-scale applications. When introduced to water, ferric chloride reacts with impurities, causing them to aggregate into larger particles called flocs, which can be easily separated through sedimentation or filtration. This makes it particularly effective in removing suspended solids, organic matter, and certain contaminants. Ferric chloride is used extensively in treating both municipal and industrial water sources, including surface water from lakes, rivers, and reservoirs, as well as groundwater, ensuring a reliable supply of clean and safe water for various needs.

Application of Ferric Chloride:

Application of Ferric Chloride:

· Coagulation and Flocculation: Ferric chloride is primarily used as a coagulant in the treatment of drinking water and wastewater. It helps to aggregate suspended particles, colloids, and organic matter, forming larger flocs that can be removed through sedimentation or filtration.

· Phosphorus Removal: In wastewater treatment, ferric chloride is effective in removing phosphorus. By precipitating phosphorus as ferric phosphate, it helps in preventing eutrophication in lakes and rivers caused due to excess nutrients. It helps in complying with the strict regulatory requirements for nutrient discharge.

· Sewage Treatment: Ferric chloride is commonly used in sewage treatment plants to enhance the removal of suspended solids and organic matter. Its coagulating properties improve the efficiency of biological treatment processes.

· Industrial Water Treatment: Industries that require high-quality water, such as food and beverage, pharmaceuticals, and textiles, often use ferric chloride for water treatment. It helps in clarifying water and removing impurities that could affect product quality.

· Odor and Corrosion Control: Ferric Chloride oxidizes hydrogen sulfide in wastewater converting it into sulfur or sulfates which helps in reducing odor and prevents pipe corrosion.

· Sludge Conditioning: It is used for sludge conditioning in wastewater treatment plants. It improves the physical properties of sludge by enhancing water removal during dewatering thus, reducing the volume of sludge generated and the disposal cost.

· Colour Removal: Effective in treating industrial wastewater with high colour levels, such as from textile dyeing, printing, or pulp and paper industries. It binds with colour-causing compounds, facilitating their removal.

· Metal Precipitation: Ferric chloride reacts with metals like arsenic, chromium, and lead, forming insoluble precipitates that can be removed through sedimentation. Commonly used in industries dealing with metal plating, mining, and electronics.

Benefits of Using Ferric Chloride:

Benefits of Using Ferric Chloride:

Ferric chloride offers several advantages some of them are the following:

- Effective Cogulation: Ferric chloride is highly effective in binding and coagulating a wide variety of impurities, including suspended particles, colloidal substances, and organic matter. Its strong coagulating properties lead to the formation of stable flocs, which are larger aggregates of impurities that can be efficiently separated through sedimentation or filtration. This significantly enhances the overall efficiency of water treatment processes, ensuring cleaner and safer water output.

- Phosphorus Removal: One of the standout features of ferric chloride is its ability to precipitate phosphorus effectively, thereby reducing its concentration in treated water. This is particularly important in preventing eutrophication, a condition where excess nutrients in water bodies lead to algal blooms and oxygen depletion, harming aquatic ecosystems. By removing phosphorus, ferric chloride supports better water quality and promotes a healthy and balanced ecosystem.

- Cost Effective: Ferric chloride is an economical choice for water treatment facilities due to its relatively low cost compared to alternative coagulants. Its high efficiency means that smaller doses are often required, further reducing material costs. Additionally, it generates smaller volumes of sludge, which lowers disposal costs and simplifies sludge management processes. These advantages make ferric chloride a financially viable option for large-scale and small-scale water treatment operations alike

- compatibility with other chemicals: Ferric chloride can be effectively used in combination with other treatment chemicals, such as lime or alum, to optimize the coagulation process. This compatibility allows for tailored treatment strategies that address specific water quality challenges. For instance, combining it with lime can help adjust pH levels while enhancing impurity removal, improving overall treatment efficiency and flexibility.

- Ease of Use: Ferric chloride is straightforward to handle and dose, making it a convenient choice for operators. It is available in liquid and solid forms, both of which can be accurately measured and applied. This ease of dosing allows for precise control over the treatment process, ensuring consistent water quality while minimizing waste. Its user-friendly properties also reduce the potential for operational errors.

- Effective Across a Broad PH Range: Unlike some coagulants that work effectively only within a narrow pH range, ferric chloride functions efficiently across a wide pH spectrum, from 4 to 11. This versatility makes it suitable for treating various types of water, including highly acidic or alkaline water, as well as different types of wastewater. Its broad pH compatibility provides flexibility and reliability in diverse treatment scenarios.

Best Practices for Using Ferric Chloride:

Best Practices for Using Ferric Chloride:

To maximize the effectiveness of ferric chloride in water treatment, consider the following best practices:

- Proper Dosage: Determining the correct dosage of ferric chloride is critical to achieving effective coagulation while minimizing negative side effects. Jar tests are commonly employed to simulate water treatment processes and identify the optimal dose based on specific water quality parameters such as turbidity, pH, and organic content. Overdosing can lead to excessive production of sludge, increasing disposal costs and complicating sludge management. Conversely, underdosing may result in incomplete coagulation, leaving impurities and suspended particles in the water. Continuous monitoring and adjustments ensure the treatment process remains efficient and cost-effective.

- Monitoring pH Level: Ferric chloride performs best within a pH range of 5.5 to 8.5, where its coagulation properties are most effective. Outside this range, the chemical reaction may be less efficient, leading to suboptimal floc formation or potential re-dissolution of impurities. Regular pH monitoring is essential, and adjustments can be made using pH modifiers like lime or sulfuric acid. Maintaining the proper pH ensures that the treated water meets regulatory standards and enhances the efficiency of downstream treatment processes.

- Mixing and Contact Time: The effectiveness of ferric chloride depends on thorough mixing with water to promote uniform distribution and maximize interaction with impurities. High-speed mixers or agitators are often used during the initial addition to achieve rapid dispersion. After mixing, allowing adequate contact time enables the formation of larger, stable flocs that can be removed during sedimentation or filtration. Insufficient mixing or inadequate contact time can compromise the quality of treated water and increase the load on subsequent processes.

- Sludge Management: The coagulation process with ferric chloride generates a significant amount of sludge, which consists of the aggregated impurities and chemical residues. Efficient sludge management practices are essential to handle the increased volume. This involves regular monitoring of sludge characteristics, such as moisture content and density, to optimize dewatering processes. Technologies like centrifuges, belt presses, or drying beds can be employed to reduce sludge volume and facilitate disposal. Proper sludge management not only reduces environmental impact but also minimizes operational costs.

- Safety Precautions: Ferric chloride is a corrosive substance that poses risks to personnel and equipment if not handled properly. To ensure safety, workers should use appropriate personal protective equipment (PPE), including gloves, goggles, and protective clothing. Storage tanks and dosing systems must be designed with corrosion-resistant materials and equipped with features to prevent leaks or spills. Emergency response measures, such as spill containment kits and eyewash stations, should be readily available to address accidental exposure or spills.

- Regular Maintenance: Regular maintenance of dosing equipment and storage systems is crucial for consistent and accurate application of ferric chloride. Corrosion or wear in pipes, pumps, and tanks can lead to equipment failures, uneven dosing, or contamination of the chemical. Routine inspections, cleaning, and calibration of equipment help prevent operational disruptions and ensure the long-term reliability of the treatment system. Proactive maintenance also minimizes the risk of unplanned downtime and reduces overall operational costs.